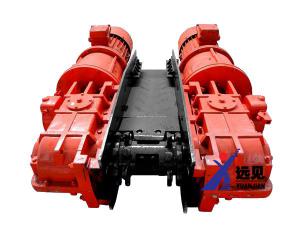

Reducer

JS75 reducer, 150 scraper reducer

- Introduce: I. Overview 1. This reducer is mainly a 75 kW reducer that is …

Product details

I. Overview

1. This reducer is mainly a 75 kW reducer that is used in conjunction with a mining scraper conveyor . This reducer is a three-stage arc gear reducer . The reducer is mounted on the side of the headstock of the conveyor and is arranged parallel to the conveyor. The four shafts of the reducer are output shafts. The four-axis splines drive the conveyor sprocket. One shaft of the reducer is connected to the motor through a coupling to complete the deceleration and power transmission.

Gear modulus and speed ratio of reducer

Speed ratio level | Pinion modulus | Pinion teeth | Big gear modulus | Gear number | Speed ratio |

***level | M s = 8.6 | 12 | M s = 8.6 | 35 | 1: 2.9167 |

second level | M n = 7 | 16 | M n = 7 | 53 | 1: 3.3125 |

Third level | M = 9 | 17 | M = 9 | 43 | 1: 2.2594 |

Total speed ratio | 1: 24.43758 | ||||

Structure

The structure of this reducer is shown in the figure. It consists of a *** circular bevel gear shaft, a second helical gear shaft, a third cylindrical gear shaft, and a fourth output shaft. The four shafts are fixed in the upper and lower cases of the reducer by rolling bearings. The material of the upper and lower cases of this reducer is HT250 gray cast iron.

Except for one shaft 7315B bearing, which is lubricated by ZL-2 (SY1412) lithium base grease, the gears and bearings are all lubricated by GB5903 N320 extreme pressure gear oil. The injection volume is 1/3 of the height of the immersed bevel gear .

The overall dimensions (length x width x height) of the reducer is 1503x959x600 .

The weight of the reducer is 1034.7kg .

This reducer can be used in reverse. Use natural cooling.

Fourth, technical requirements

Gear accuracy grade

Bevel gears and cylindrical gears are manufactured with JB180 , 9-8-8DC grade precision.

2. Gear and shaft materials

The reducer shaft gears and gears are made of 20CrMnTi high-strength alloy material for quenching and tempering, and the tooth surface is carburized and quenched to improve the service life of the gear. The four shafts of the reducer are quenched and tempered with 40MnVBhigh-strength alloy steel.

3. Gear contact accuracy requirements

( 1 ) The contact spots of the arc gear are not less than 50% along the length and height of the working tooth, and the minimum tooth side clearance is 0.17 mm.

( 2 ) The contact spot of the cylindrical helical gear is no less than 50% along the length of the working tooth and no less than 40%along the tooth height . The minimum tooth side clearance is 0.21 mm.

( 3 ) The contact spot of the cylindrical spur gear is not less than 50% along the length of the working tooth, not less than 40% along the tooth height , and the tooth side clearance is not less than 0.21 mm.

4. Bearing axial clearance

*** The shaft clearance is 0.05-0.12 mm, the second shaft clearance is 0.06-0.15 mm, the third shaft clearance is 0.07-0.18 mm, and the fourth shaft clearance is 0.2-0.4 mm. The bearing clearance of each shaft is adjusted by the adjusting pad.

Five, reducer assembly

1. Collect all the parts to be assembled, and clean and dry them. In addition to the surface of the sealant coating, the processing surface is coated with clear oil. The non-machined surfaces in the upper and lower cases are coated with red oil-resistant paint. Large batches can be selected.

2. Assemble each shaft assembly.

3. When assembling the reducer, the sequence is from one axis to four axes. Measure the tooth side clearance with a dial indicator and determine the bearing clearance with a plug gauge.

4. Apply sealing paint to close the box and assemble the shaft bearing glands. Tighten all bolts.

5. After the reducer is assembled, rotate the shaft by hand, the rotation does not get stuck, and the forward and reverse rotation is flexible.

6. Precautions during assembly

( 1 ) All bearings and gears can be installed hot. Never press with a press. You can use a small copper hammer (copper rod) to hit the assembly.

( 2 ) Before closing the box, you must check whether there are foreign objects in the box

( 3 ) The joint surface of the upper and lower boxes and the end face of the bearing cover should be coated with sealing paint. During running, there should be no oil leakage on the joint surface and the seal on the shaft extension.

( 4 ) The rear edges of the upper and lower boxes should be flush with each other, and the amount of displacement between each side should not be greater than 2 mm.

( 5 ) Check if the vent plug is breathable.

( 6 ) Fill a proper amount of ZL-2 grease into the one-shaft sleeve and the four-shaft seal sleeve .

( 7 ) Mount the nameplate of the reducer on the outer end face of the bearing gland. The name of the factory, product model name, total transmission ratio, factory number, safety standard number, etc. are indicated on the nameplate.

Six, reducer factory test, type test

1. The assembled reducer shall be subjected to no-load test and temperature rise test one by one. The noise test shall comply with thegeneral technical conditions of MT / T148 reducer for scraper conveyor and MT / T105 scraper.

2. The type test of the reducer shall meet the requirements of MT / T148 and MT / T105 standards.

Seven, reducer use and maintenance

1. The reducer is used in conjunction with the conveyor. Except for the maintenance and use requirements of the conveyor, every shift and daily check whether the oil leakage and the oil volume meet the requirements. The cause of oil leakage detection shall be dealt with in time.

2. Remove foreign matter on the reducer every shift. Check the gearbox for abnormal sounds and vibrations. The oil temperature should not exceed 100C °.

3. Check the oil quality every month. If it is unqualified or there are too many impurities, it should be replaced.

4. Replace with new lubricant in half a year. And clean the impurities in the box.

5. The reducer is overhauled once a year, and should generally be carried out in the ground workshop. Inspect all gear surfaces. Spots and adhesive damage should be replaced. There is no abnormal overload operation during the use of the reducer, and the bearing can be evaluated for replacement according to the bearing life index. All seals must be replaced. The specifications of the replaced parts are found out in the drawing details.

6. After replacing parts in the reducer, refer to the "Five" requirements in this manual.

Assembly.

7. During transportation of the reducer, the lubricant in the reducer is drained off, and the exposed shaft head is greased, and the exposed part is wrapped.

During storage of the reducer, the input shaft must be turned by hand every month, and the output shaft must be rotated at least one shaft. Vent plugs must be replaced with non-perforated plugs during storage. Conditional tank is filled with oil to prevent gears from rusting. When using, you need to clean the cabinet with the same grade of lubricant, and then add working lubricant.

Eighth, reducer failure causes and treatment measures

Reducer failure causes and treatment measures

malfunction | the reason | Measures |

Reducer oil temperature is too high | Unqualified lubricants or excessive use time Too much lubricant Damaged parts The exterior of the cabinet is covered by debris or dust | Change lubricant Oil on request Repair or replacement Remove debris or dust |

Oil leak | Damaged oil seal Reducer box joint surface or bearing end cap bolts are not tightened | Replace oil seal Tighten the bolts on the joint surface of the box or the bearing end cap to allow the liquid sealant |

Reducer sound is abnormal | Gear close Debris in the lubricant Worn or damaged gear bearings Input shaft is different from motor shaft Excessive axial clearance | Check and adjust Remove debris or change lubricant Replace gears or bearings Adjust so that the coaxiality is not greater than 0.5mm Adjust bearing axial clearance |

Nine, quality assurance

The user is responsible for free repair or replacement if the product is damaged or fails to work normally due to poor manufacturing quality within six months from the date of shipment, subject to the conditions of use and storage stipulated in the maintenance manual.If users need or have questions, please contact us by phone or fax.

Details of JS75 reducer

Code | 3JS11 / 00 | name | JS30 type reducer | |

Serial number | Code | name | Quantity | Note |

1 | 1JS10 / 01 | ***axis | 1 | |

2 | GB13871-1992 | Sealing ring | 1 | |

3 | 1JS10 / 02 | Second axis | 1 | |

4 | 1JS10 / 03 | Third axis | 1 | |

5 | 1JS10 / 04 | Fourth axis | 1 | |

6 | 1JS10 / 00-4 | Adjustment mats | Determined according to actual situation | |

7 | 1ST0102-17 | Screw plug | 2 | |

8 | 1JS10 / 00-7 | Adjustment mats | Determined according to actual situation | |

9 | 1JS10 / 00-8 | Adjustment mats | Determined according to actual situation | |

10 | 1JS10 / 00-10 | Upper box | 1 | |

11 | 1JS10 / 00-11 | Lower case | 1 | |

12 | 1ST0102-11 | Screw plug | 1 | |

13 | 1ST010205 | Breathable plug | 1 | |