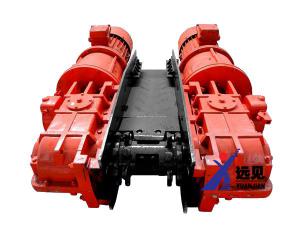

Reducer

JS40 scraper reducer, 40T scraper reducer, SGB620 / 40T scraper reducer

- Introduce: I. Overview: The reducer has the characteristics of large carrying capacity, h…

Product details

I. Overview:

The reducer has the characteristics of large carrying capacity, high transmission efficiency, low noise, small size, light weight and long life. It is suitable for transmission devices where the input shaft and output shaft are arranged vertically, such as scraper conveyors, belt conveyors and various transportation machinery. It can also be used in metallurgy, mining, chemical, cement, construction, light industry, energy and other A general mechanical transmission.

JS40 model composition and representative meaning:

name | J | S | 40 |

significance | Reducer | Parallel arrangement | Main parameter code (transmitted power KW) |

Technical characteristics:

name | model | Transmission ratio | Dimensions (mm) | Total weight (t) |

Reducer | JS40 | 24.565 | 1150 × 834 × 470 | 0.656 |

Structure type and function:

The reducer consists of a pair of circular bevel gears, a pair of helical gears, and a pair of spur gears. The three-stage reduction gear has a total reduction ratio of 1: 24.564. ***, the second and third shaft bearings are single row tapered roller bearings, and the fourth shaft is double row radial spherical roller bearings. *** The lock nut on the shaft is used to fix the bearing and ensure that the axial clearance of the bearing is 0.05 to0.1 mm. The axial clearance of the second, third and fourth bearings is guaranteed by adjusting pads, of which two, three The axial clearance of the shaft bearing is 0.08 to 0.15 mm, and the axial clearance of the four-axis bearing is 0.06 to 0.15 mm. During assembly, the axial position of the circular arc bevel gear should be adjusted appropriately to ensure the meshing backlash and contact spots. The axial displacement of the circular arc bevel gear is adjusted by the adjusting nut, and the large circular bevel gear is adjusted by the adjustment pad.向 位置。 To the location. In order to achieve better meshing accuracy, the adjusted backlash of a pair of circular arc bevel gears is not less than 0.17 mm, and the contact spots are not less than 50 % in the direction of tooth length and tooth height.

Injected into the reducer 150 No. industrial gear oil, a large injection volume is immersed in the arc of a circle bevel gear 1 / 3 , in order to ensure adequate lubrication of the various parts.

Fourth, use and maintenance precautions:

1. Check whether the connecting bolts of the reducer are loose in each shift, and tighten them in time if they are found loose.

2. Always pay attention to the working conditions of the reducer. If abnormal noise, excessive temperature rise or leakage of sealing surfaces is found, it should be handled in time; the oil temperature must not exceed 80 ℃; the gear tooth surface must not have obvious wear and tear. Corrosion; each part should be adjusted properly according to the prescribed clearance during maintenance.

V. Lubrication of the machine:

Serial number | Part Name | Lubrication area | Fill point | Lubricant grade | Note |

1 | Reducer machine | Bearing, gear | Into the box | No. 150 industrial gear oil | Maintenance oiling |

2 | Reducer *** shaft | Bearing | 1 | Calcium Sodium GreaseZGN-2 | Fill up once a month |

6. Possible faults and treatment methods:

Serial number | Therefore,failure | The original reason | Prevention and treatment |

1 | Reducer operation sound is abnormal | Gear meshing is not good | Adjust the mesh clearance |

2 | Heavy bearing or gear wear; excessive axial clearance | Replace worn gears or adjust the bearing's axial clearance |

Seven, repair and acceptance of reducer parts:

When repairing the reducer, the worn gears, damaged rubber seals, bearings and other parts should be replaced, and the loose keys should be reconfigured. Pay attention to the following points when installing:

(1) processing in conjunction with the vertical surface of the casing to be trimmed, cleaned to remove dirt, after closing the tank port side gap not greater than 0.0lmm .

(2) Install the bearing: heat the bearing to 90 ℃ ~ 110 ℃ with oil and install it on the shaft. ***, two, three, and four shafts are assembled into components according to the position requirements and then put into the box. The drawings stipulate that the bearing caps at all levels of the lower box are installed to adjust the clearance.

(3) Adjustment of gear contact area and tooth side clearance:

When assembling the reducer, adjusting the contact area and the side clearance is a more meticulous work. When adjusting, it should be adjusted according to regulations, be careful and responsible, and be meticulous to ensure the correct meshing of the gears to extend the service life of the gears.

When the arc bevel gear is found to be incorrect during installation, it can be adjusted according to the following table. The solid arrow indicates the adjustment of the contact area; the dotted arrow indicates the adjustment of the tooth clearance. If satisfactory contact accuracy cannot be obtained after adjustment, it should be replaced in pairs or selected to achieve a more satisfactory contact area.

(4) In order to ensure that the joint surface of the box is not leaking oil, the joint surface should be cleaned, then apply a layer of sealant, and tighten the bolts after closing the upper and lower boxes.

After the reducer is repaired, a short test and a load test should be performed:

Reducer injection shall be tested 150 number or industrial gear oil 24 No. cylinder oil, the injection amount of the NPC dip Park arc bevel gear 1 / 3 . The operation should be smooth and normal, without shock vibration and uneven noise, and there should be no leakage at each joint surface and seal. Check the tooth meshing condition: the height of the contact spot along the circular bevel gear and the tooth length is not less than 50 %; the height of the contact spot along the cylindrical gear is not less than 40 %; the tooth length is not less than 50 %; the full load test oil temperature must not More than 80 %; there must be no obvious pitting and wear on the gear tooth surface.

Transportation and storage:

1. Transportation: This machine does not need to be packed during transportation. The name of the factory, product model and name, transmission ratio, factory number, safety standard number, etc. should be indicated on the nameplate of the machine.

When loading or unloading the truck, strictly follow the lifting mark for lifting. It should not be subjected to severe vibration and impact during transportation.

2. Storage: The machine should be stored in a dry, ventilated, acid-free, rain- and moisture-proof place.