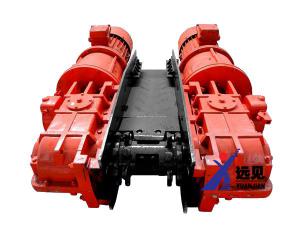

Sprocket shaft group

630 series sprocket shaft group (figure number 86S010101)

- Introduce: [Name] sprocket assembly [Figure No.] 86S010101 Applicable models: S…

Product details

[Name] sprocket assembly

[Figure No.] 86S010101

Applicable models: SGZ630 series scraper conveyor

The sprocket shaft group is also called the sprocket assembly, which is suitable for scraper conveyors in coal mines, and scraper transferers for grooves.

【use】

86S010101 sprocket shaft group is an important part of the head of the comprehensive mining scraper. In coal mining, the sprocket is driven by the reducer, and the chain drives the scraper to run in the central groove, so as to achieve the purpose of transporting coal and other materials.

【structure】

86S010101 sprocket shaft is assembled on the headstock and tailstock of the head drive, and is mainly composed of end covers, bearing housings, sprocket teeth, sprocket shafts, floating seal ring assemblies, rolling bearings and rollers.

[Material] 42CrMo high quality alloy steel

The scraper chain is driven by a sprocket, and the sprocket shaft is a part of the entire conveyor that bears huge torque. The greater the transport capacity of the scraper conveyor, the longer the laying length, and the greater the torque transmitted by the sprocket. This requires that the sprocket not only has high strength and wear resistance, but also has toughness and can withstand pulsating loads and additional impact loads during work. Therefore, the sprocket should be made of high-quality steel.

[Craft]

Forging process. 86S010101 sprocket is machined by machining center, and the tooth surface is quenched. The sprocket requires no defects such as cracks, interlayers, wrinkles, forging injuries, slag inclusion, and scarring on the surface of the forging. After running the sprocket assembly for 6 months, install it after turning it 180 ° so that both sides of the sprocket teeth wear evenly.

【parameter】

Overview of main technical parameters: total length of 961mm, height of both ends of 360mm, distance between two positioning holes is 665mm, and positioning hole size is 45mm. The sprocket body of this type of sprocket shaft group uses 8-tooth 42CrMo forged heat-treated sprocket. The outer diameter of the sprocket is 510mm. The medium and double chain sprocket is equipped with a 26 × 92 grade C heat-treated chain. 120mm.

【classification】

86S010101 sprocket shaft group is divided into: head sprocket shaft group, tail sprocket shaft group.

According to applicable models, it can be divided into: 630, 730, 764, 800, 830, 900, 1000, 1200, 1250, 1400 and other models.

According to the supporting main plant, it is divided into: Zhangjiakou coal machine sprocket shaft group, Shandong mining machine sprocket shaft group, Northwest Benniu sprocket shaft group, Shanxi coal machine factory sprocket shaft group, Zheng coal machine sprocket shaft group, Huainan long wall sprocket shaft group, Linzhou Heavy Machinery Sprocket Shaft Group, Sany Heavy Industry Sprocket Shaft Group, etc.

【service】

Quality assurance: depending on product quality like life. Our products are in strict accordance with the national quality management system certification GB / T19001 / ISO9001: 2015 standards, adopt advanced design concepts, use modern production equipment (such as CNC double-sided welding machines, intelligent robots, machining centers, etc.), a complete product testing system, Guarantee product quality and cost-effective.

Price guarantee: market preferential prices. Our company's products are made of well-known brands at home and abroad, and provide preferential prices on the basis of ensuring quality.

Delivery guarantee: According to customer requirements, guarantee delivery on time. If there are special requirements that need to be completed in advance, our company can specially organize production forces to meet customer needs.

After-sale guarantee: The after-sales team of ******. With fast and effective information feedback system, our company provides customers with free and efficient maintenance services. Provides analysis and solutions to common problems with sprocket assemblies. Through the maintenance and reuse of the sprocket shaft group, the service life is prolonged and the enterprise can save procurement costs.

【Honor】

International standard recognition certificate, mining product safety mark certificate, quality management system certification, key project construction award (Luoyang Yichuan), member unit of Luoyang Network Business Association, etc.

Luoyang Yuanjian Mining Equipment Co., Ltd. was founded in 1996. It is an expert in coal mining equipment for 23 years.