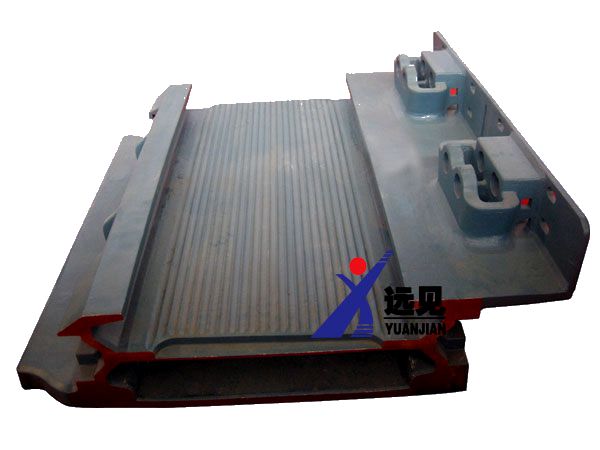

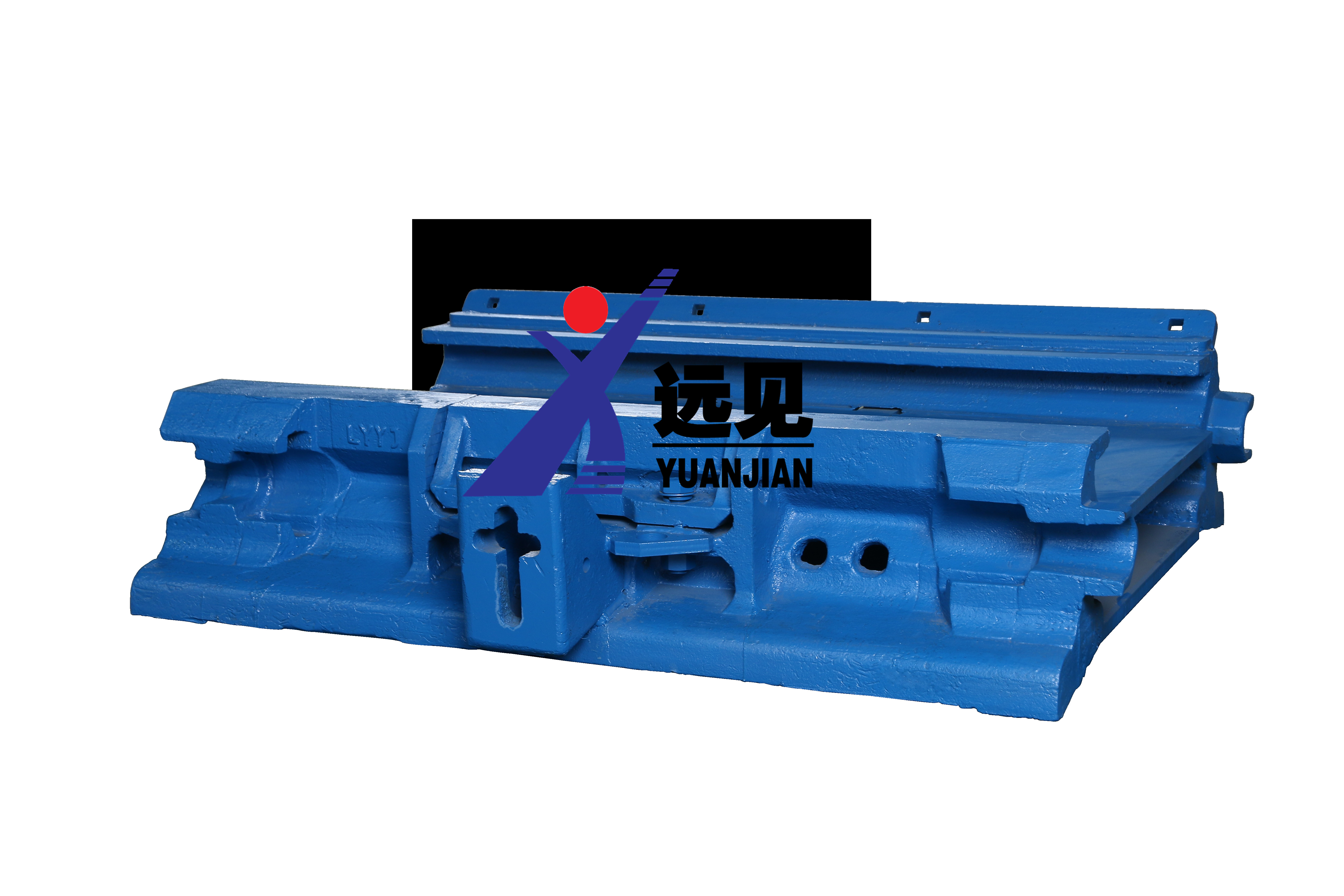

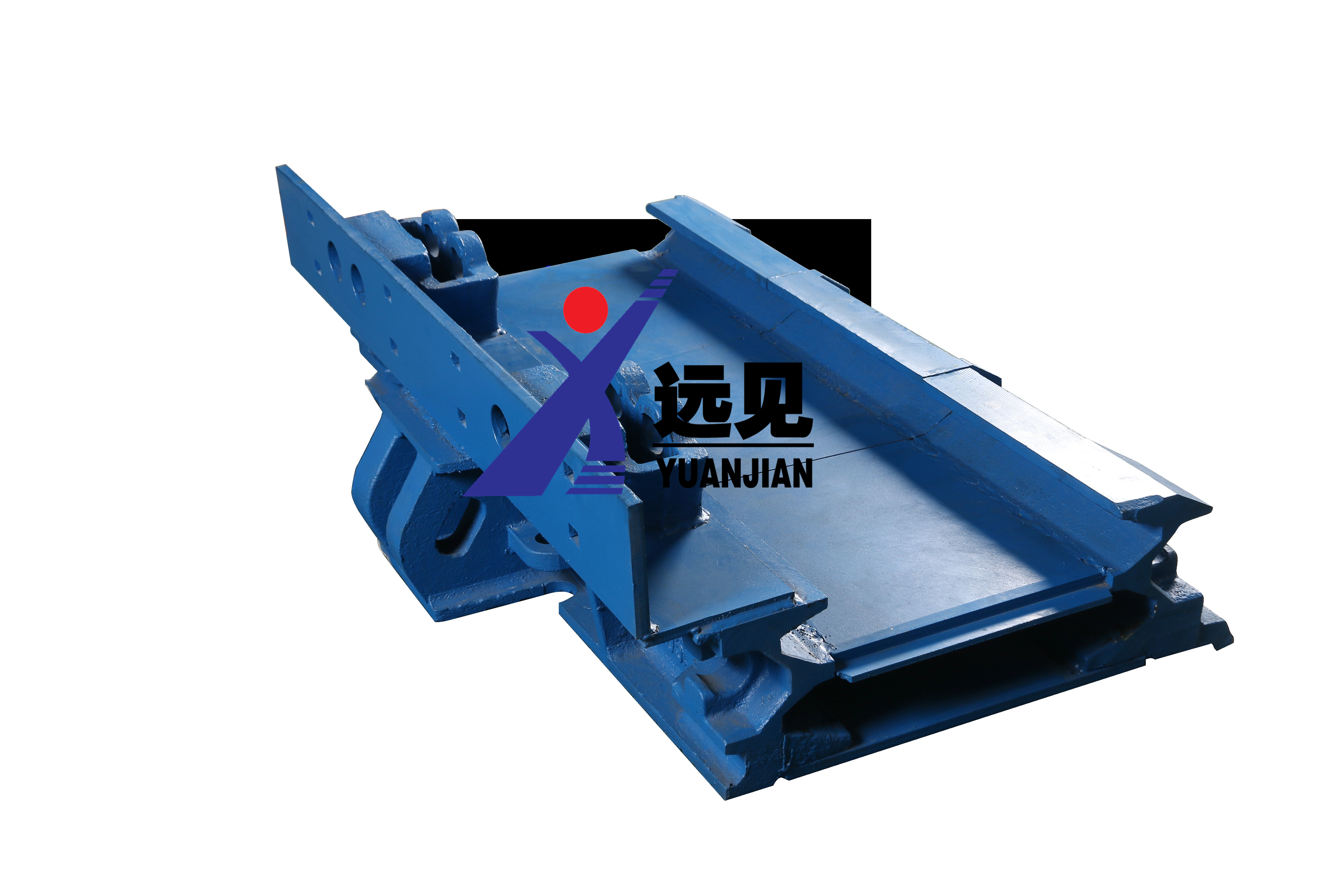

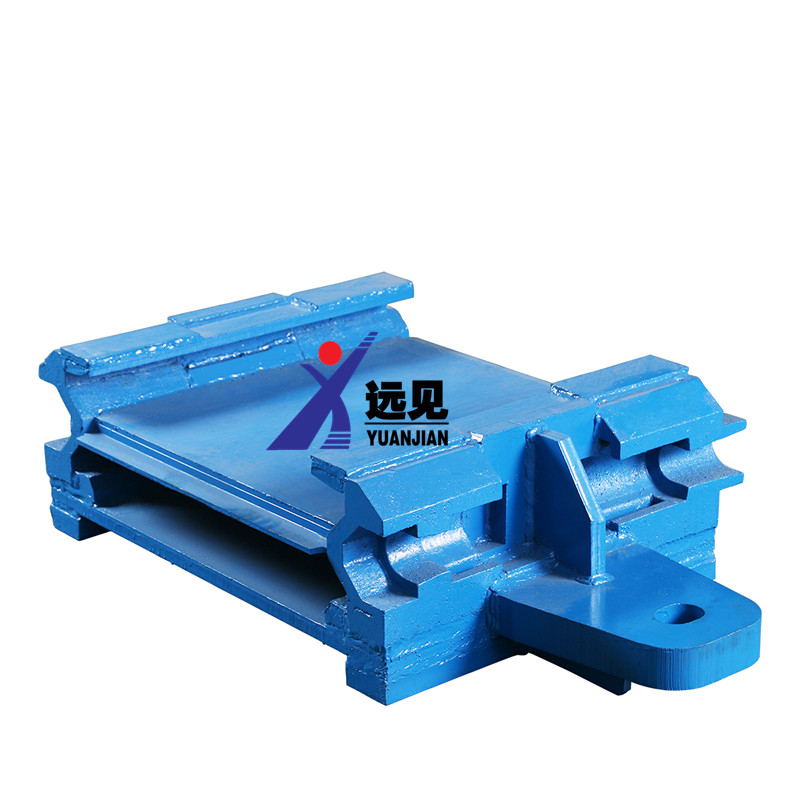

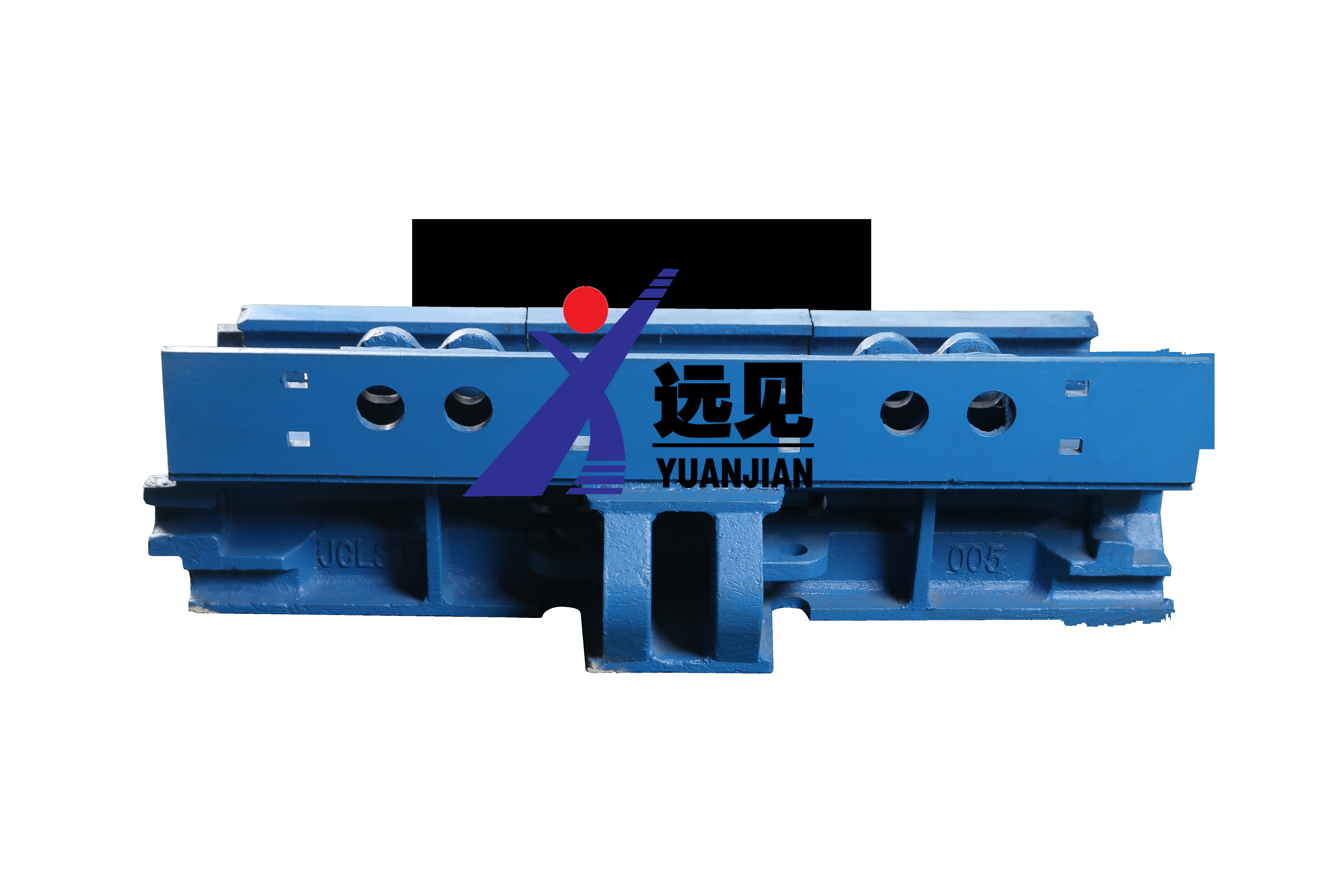

Scraper casting middle trough, fully mechanized middle trough, middle coal mine trough, underground middle trough

- Brief introduction: Casting the central groove is generally suitable for comprehensive mining scraper conveyors.The main supporting manufacturers include Northwest Coal Mining Machine(Ningxia Dibeniu),Zhangjiakou Coal Mining Machine,Shandong Mining Machine,Shanxi Coal Mining Factory and other manufacturers.The customer provides the drawing number of the middle slot of the OEM or provides a drawing,which can be customized. The company's production mainly uses the V method casting process,and its characteristics are mainly as follows: 1.Good casting formability,which is conducive to the formation of products with clear contours and high surface finish; 2.Compact casting structure and good mechanical properties; 3.Dimension precision High,small casting machining margin; 4.The internal and external pressure difference of the sand mold is that the hardness of each part of the sand mold is uniform and high(above 85); 5.The sand box is easy to lift,and the draft angle is small(0~-1°) 6.The cavity is not easy to deform under the heat of the metal liquid. 7.During the pouring,because the sand box maintains the vacuum state,it is beneficial for the metal liquid to fill the cavity. The casting grooves and central casting grooves of the scraper produced by the company mainly include:630,730,764,800,830,900,1000,1200,etc.

Product Details

Casting the central groove is generally suitable for comprehensive mining scraper conveyors.The main supporting manufacturers include Northwest Coal Mining Machine(Ningxia Dibeniu),Zhangjiakou Coal Mining Machine,Shandong Mining Machine,Shanxi Coal Mining Factory and other manufacturers.The customer provides the drawing number of the middle slot of the OEM or provides a drawing,which can be customized.

The company's production mainly uses the V method casting process,and its characteristics are mainly as follows:

1.Good casting formability,which is conducive to the formation of products with clear contours and high surface finish;

2.Compact casting structure and good mechanical properties;

3.Dimension precision High,small casting machining margin;

4.The internal and external pressure difference of the sand mold is that the hardness of each part of the sand mold is uniform and high(above 85);

5.The sand box is easy to lift,and the draft angle is small(0~-1°)

6.The cavity is not easy to deform under the heat of the metal liquid.

7.During the pouring,because the sand box maintains the vacuum state,it is beneficial for the metal liquid to fill the cavity.

The casting grooves and central casting grooves of the scraper produced by the company mainly include:630,730,764,800,830,900,1000,1200,etc.

- Prev:40 central groove