Ning Xia Di Benniu SGZ630 / 220 central trough

- Brief introduction: [Name] Ningxia Dibenniu SGZ630 / 220 central trough [Applicable models] SGZ630 / 220 scraper conveyor for comprehensive mining 【use】 The central trough of the Northwest Benniu 630 is the main component of the scraper conveyor. It is not only the running track of the scraper chain, but also the running track of the shearer, or the coal-containing running channel. The middle slot is also the load-bearing part of the material. During the operation, it is subject to the severe friction of coal, scraper and chain, and it is a component with high usage and consumption. 【structure】 The central trough of Northwest Benniu 630 belongs to the accessories for comprehensive mining scraper conveyors. It is the body of the scraper conveyor. It consists of a middle plate, a trough, a sealing bottom plate, a rail seat and a connecting plate. For scraper chain return. Groove: A connecting pin is welded on one end of the groove, and the connecting pin is inserted into the groove of the adjacent central groove to realize mutual positioning. Medium plate: The position of the middle plate chain is carbon arc surfacing 1.5 to 2mm thick wear-resistant alloy to increase wear resistance and improve service life. [Material] Middle plate: 45 steel Groove help: 30SiMn Advantages: The impact resistance is higher than ordinary steel plates, the average hardness is higher, the friction coefficient is low, the acid and alkali resistance and salt water corrosion resistance are high, the running resistance and noise are low, and it is not easy to deform after being stressed. [Craft] V method casting process (groove), sand casting, welding process. National quality management system certification GB / T19001 / ISO9001: 2015 standard. We can customize the processing according to the drawing number or drawing provided by the customer's central slot. (V method casting advantages: 1. Good casting formability, which is conducive to the formation of products with clear contours and high surface finish; 2. Compact casting structure and good mechanical properties; 3. High dimensional precision and small machining allowance of castings; 4. The internal and external pressure difference of the sand mold is that the hardness of each part of the sand mold is uniform and high ( more than 85 ); 5. The sand box is easy to remove the mold, and the draft angle is small ( 0 ~ -1 °); 6. The thermal effect of the metal liquid The cavity is not easy to be deformed; 7. During the pouring, because the sand box is kept in a vacuum state, it is beneficial for the metal cavity to fill the cavity.) 【parameter】 Specifications Model: SGZ630 / 220 type Main dimensions: length: 1500mm width: 630mm thickness: 208mm 【classification】 The central tank is mainly used for scraper conveyors and transferers in coal mines. According to the production form: ordinary middle trough, open sunroof middle trough. According to the manufacturer of the host: Northwest Benniu central trough, Zhangjiakou coal trough middle trough, Shandong miner central trough, Shanxi coal miner central trough, Zheng coal trough central trough. According to the scraper model: 630 middle groove, 730 middle groove, 830 middle groove, 880 middle groove, 1000 middle groove, etc. 【service】 Quality assurance: depending on product quality like life. Our products are strictly in accordance with the national quality management system certification GB / T19001 / ISO9001: 2015 standards, adopt advanced design concepts, use modern production equipment (such as CNC double-sided welding machines, intelligent manipulators, machining centers, etc.), perfect product testing system, Guarantee product quality. Price guarantee: market preferential prices. Our company's product materials are selected from domestic and foreign brands. On the basis of ensuring quality, we provide preferential market prices. Delivery guarantee: According to customer requirements, guarantee delivery on time. If there are special requirements that need to be completed in advance, our company can specially organize production forces to meet customer needs. After-sale guarantee: The after-sales team of ******. Our company uses a fast and effective information feedback system to ensure that customers are provided with free and efficient maintenance services. Provide complete problem analysis and solutions for the central tank, prolong the service life of the central tank, and help enterprises save procurement costs. 【Honor】 International standard recognition certificate, mining product safety mark certificate, quality management system certification, key project construction award (Luoyang Yichuan), member unit of Luoyang Network Business Association, etc. Luoyang Yuanjian Mining Equipment Co., Ltd. was founded in 1996. It is an expert in coal mining equipment for 23 years.

Product Details

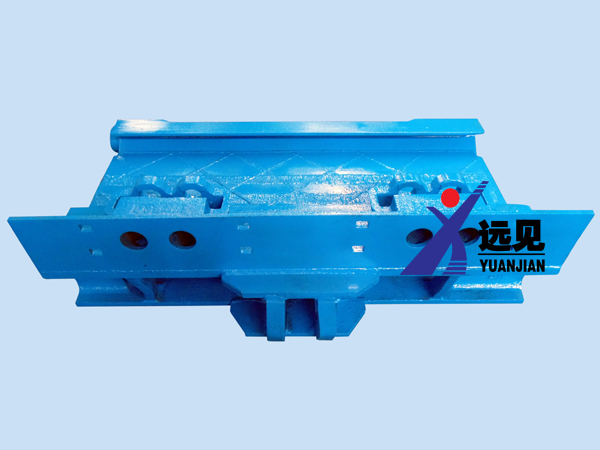

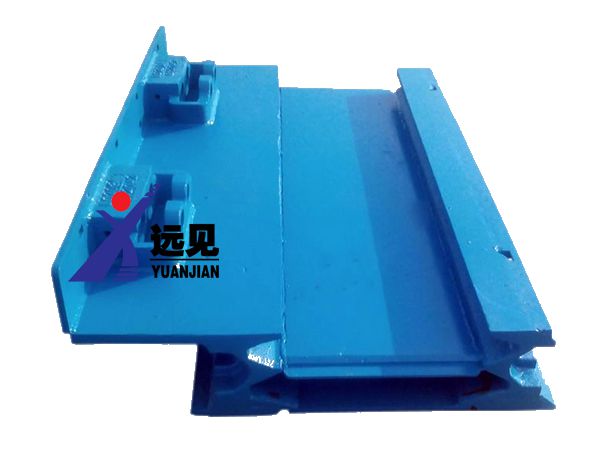

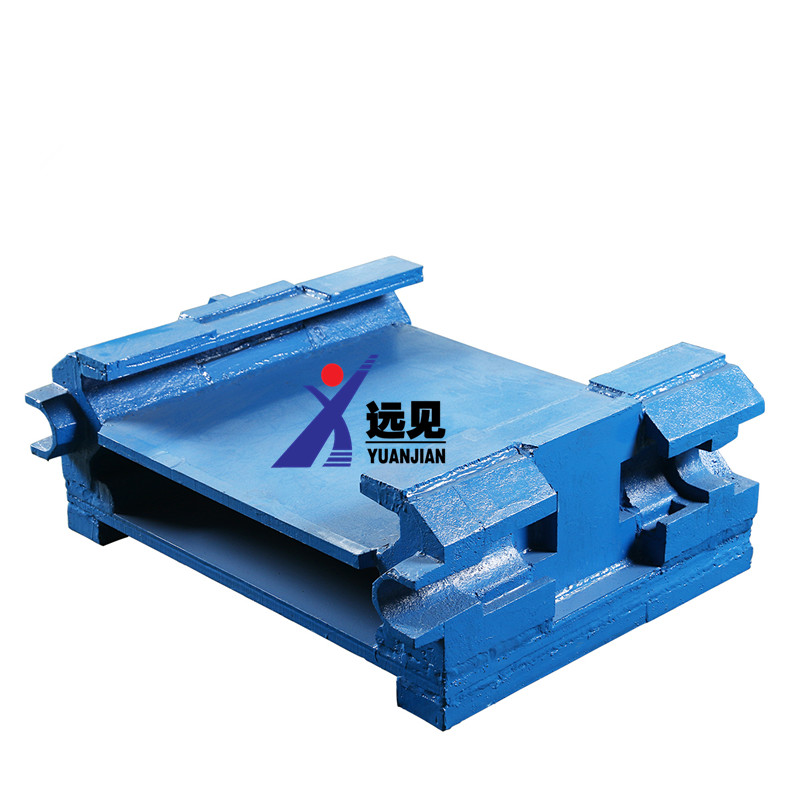

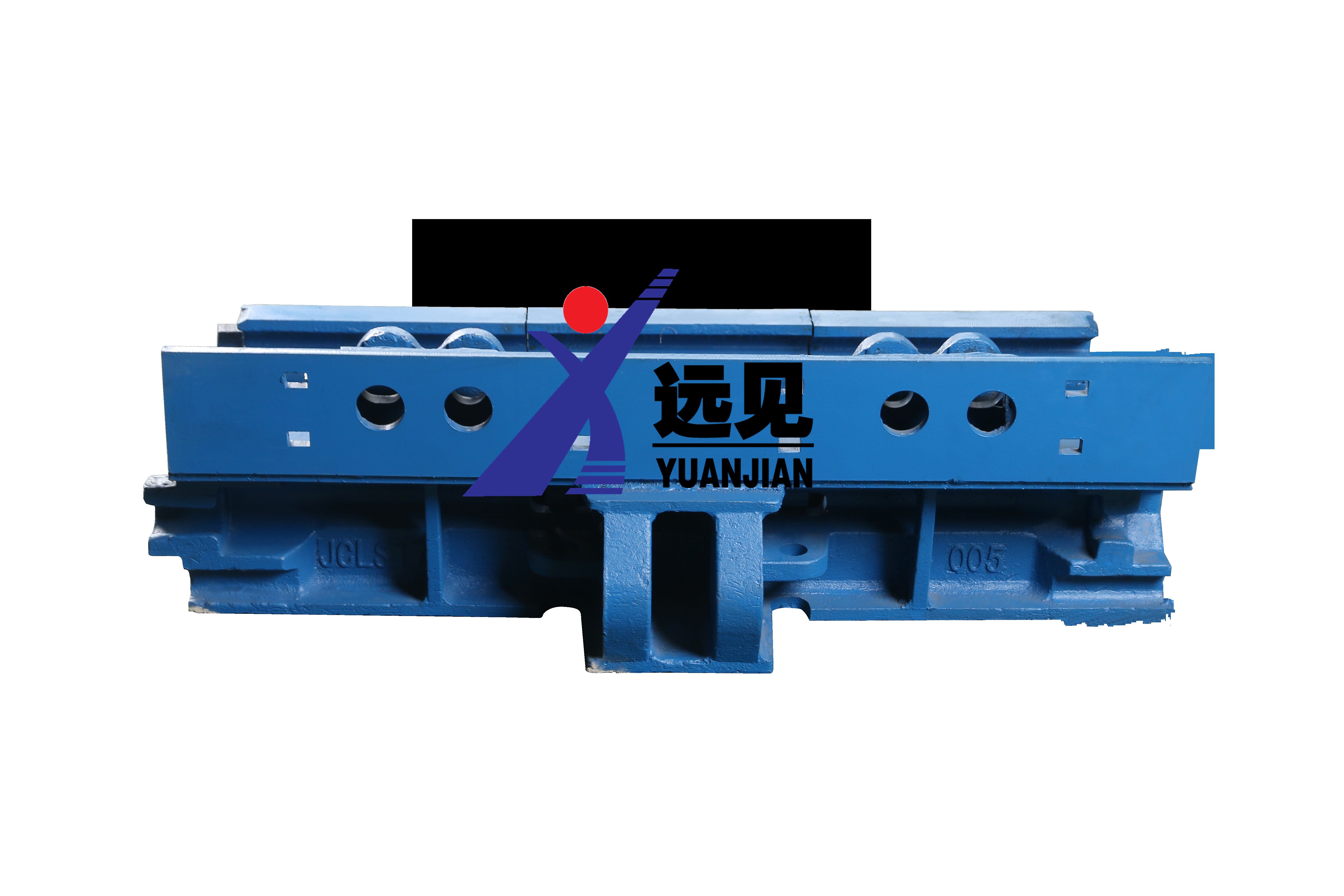

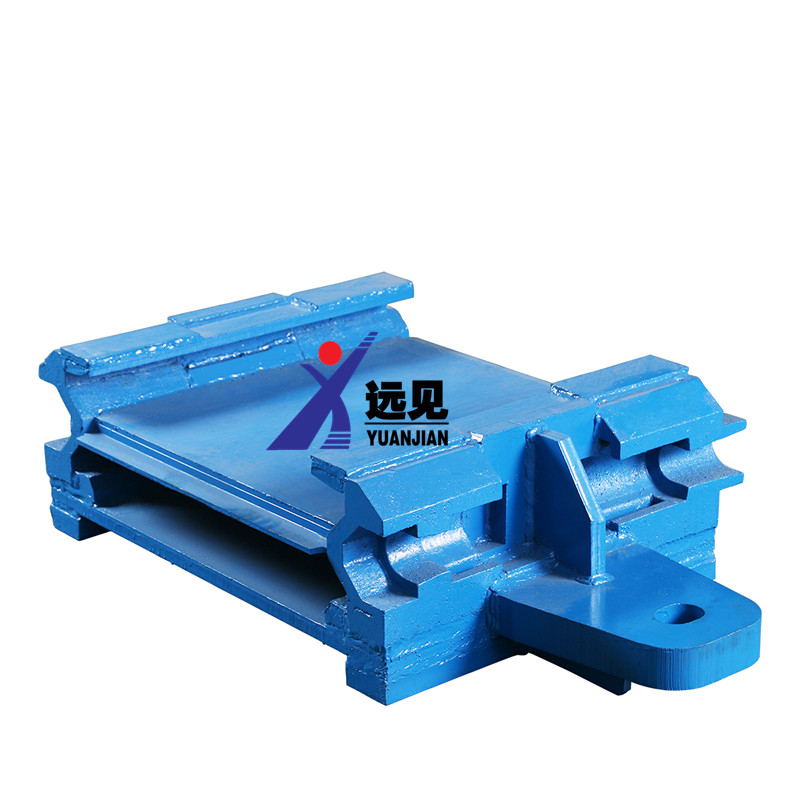

[Name] Ningxia Dibenniu SGZ630 / 220 central trough

[Applicable models] SGZ630 / 220 scraper conveyor for comprehensive mining

【use】

The central trough of the Northwest Benniu 630 is the main component of the scraper conveyor. It is not only the running track of the scraper chain, but also the running track of the shearer, or the coal-containing running channel. The middle slot is also the load-bearing part of the material. During the operation, it is subject to the severe friction of coal, scraper and chain, and it is a component with high usage and consumption.

【structure】

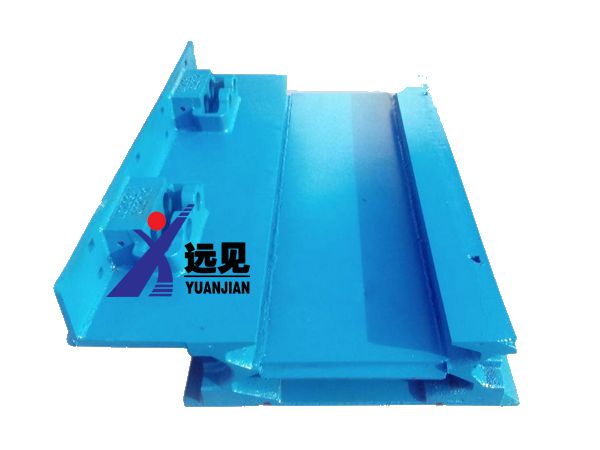

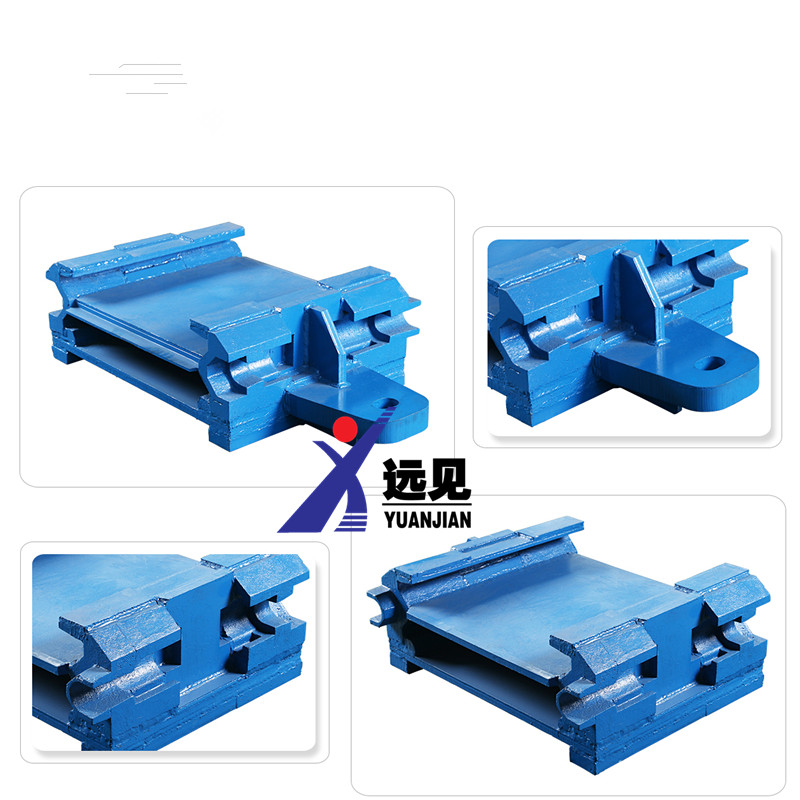

The central trough of Northwest Benniu 630 belongs to the accessories for comprehensive mining scraper conveyors. It is the body of the scraper conveyor. It consists of a middle plate, a trough, a sealing bottom plate, a rail seat and a connecting plate. For scraper chain return.

Groove: A connecting pin is welded on one end of the groove, and the connecting pin is inserted into the groove of the adjacent central groove to realize mutual positioning.

Medium plate: The position of the middle plate chain is carbon arc surfacing 1.5 to 2mm thick wear-resistant alloy to increase wear resistance and improve service life.

[Material]

Middle plate: 45 steel

Groove help: 30SiMn

Advantages: The impact resistance is higher than ordinary steel plates, the average hardness is higher, the friction coefficient is low, the acid and alkali resistance and salt water corrosion resistance are high, the running resistance and noise are low, and it is not easy to deform after being stressed.

[Craft]

V method casting process (groove), sand casting, welding process.

National quality management system certification GB / T19001 / ISO9001: 2015 standard.

We can customize the processing according to the drawing number or drawing provided by the customer's central slot.

(V method casting advantages: 1. Good casting formability, which is conducive to the formation of products with clear contours and high surface finish; 2. Compact casting structure and good mechanical properties; 3. High dimensional precision and small machining allowance of castings; 4. The internal and external pressure difference of the sand mold is that the hardness of each part of the sand mold is uniform and high ( more than 85 ); 5. The sand box is easy to remove the mold, and the draft angle is small ( 0 ~ -1 °); 6. The thermal effect of the metal liquid The cavity is not easy to be deformed; 7. During the pouring, because the sand box is kept in a vacuum state, it is beneficial for the metal cavity to fill the cavity.)

【parameter】

Specifications Model: SGZ630 / 220 type

Main dimensions: length: 1500mm width: 630mm thickness: 208mm

【classification】

The central tank is mainly used for scraper conveyors and transferers in coal mines.

According to the production form: ordinary middle trough, open sunroof middle trough.

According to the manufacturer of the host: Northwest Benniu central trough, Zhangjiakou coal trough middle trough, Shandong miner central trough, Shanxi coal miner central trough, Zheng coal trough central trough.

According to the scraper model: 630 middle groove, 730 middle groove, 830 middle groove, 880 middle groove, 1000 middle groove, etc.

【service】

Quality assurance: depending on product quality like life. Our products are strictly in accordance with the national quality management system certification GB / T19001 / ISO9001: 2015 standards, adopt advanced design concepts, use modern production equipment (such as CNC double-sided welding machines, intelligent manipulators, machining centers, etc.), perfect product testing system, Guarantee product quality.

Price guarantee: market preferential prices. Our company's product materials are selected from domestic and foreign brands. On the basis of ensuring quality, we provide preferential market prices.

Delivery guarantee: According to customer requirements, guarantee delivery on time. If there are special requirements that need to be completed in advance, our company can specially organize production forces to meet customer needs.

After-sale guarantee: The after-sales team of ******. Our company uses a fast and effective information feedback system to ensure that customers are provided with free and efficient maintenance services. Provide complete problem analysis and solutions for the central tank, prolong the service life of the central tank, and help enterprises save procurement costs.

【Honor】

International standard recognition certificate, mining product safety mark certificate, quality management system certification, key project construction award (Luoyang Yichuan), member unit of Luoyang Network Business Association, etc.

Luoyang Yuanjian Mining Equipment Co., Ltd. was founded in 1996. It is an expert in coal mining equipment for 23 years.