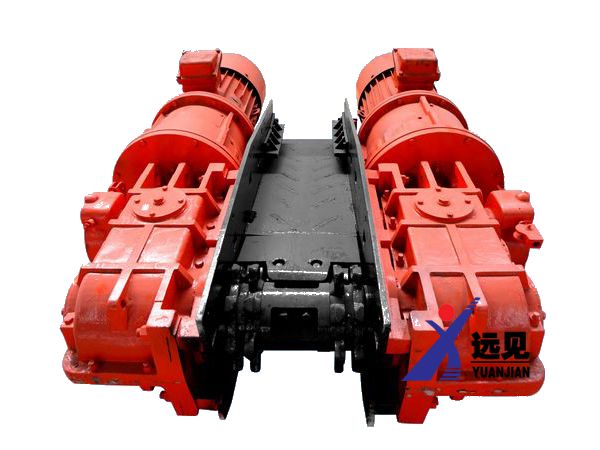

Small 40 scraper conveyor, small 40 slide

- Brief introduction: SGB420 / 40TX scraper conveyor is mainly used for conveying coal in the coal mining face of the gently inclined thin coal seam and the Central Plains coal seam below the coal mine. This product has the characteristics of strong transportation, stable transmission, simple structure, convenient assembly and disassembly, easy maintenance, safety and reliability. Its type, size and main technical performance are in accordance with MT / T105-93 "Types and parameters of mining scraper conveying models. "Provisions. It can be equipped with double transmission according to requirements, that is, the scraper uses two 40KW motors and two JS40 reducers. The maximum laying length can reach 160m, which greatly improves the transportation volume compared with 30 scrapers. Structure and performance of main parts 1. Overall structure: This product is mainly composed of transmission parts, moving beams, transition grooves, middle grooves, scraper chains, tails, left and right baffles and other components. 2. The main component structure and working principle Transmission part: The transmission part is mainly composed of motor, reducer, sprocket, headstock, tongue plate, blind shaft, chain tensioner and other components. The coupling cover connects the motor and reducer into a whole, and the power is transmitted to the The sprocket and sprocket drive the scraper to form a closed stepless transmission chain, which plays the role of transporting coal. 3. Reducer: The reducer is a three-stage conical cylindrical gear transmission with a transmission power of 40kw and a transmission ratio of 24.564. In order to ensure the normal operation of the bearing, the axial clearance of the bearing should be appropriately adjusted: the *** axis is 0.04--0.1; the second axis is 0.08-0.15; the third axis is 0.07-0.15; the fourth axis is 0.2-0.4 The axial position of the arc bevel gear should also be adjusted appropriately to ensure a reasonable meshing backlash and contact spots. The meshing backlash is not less than 0.17mm, and the contact spots are not less than 50% in the direction of tooth length and tooth height. *** The axial clearance of the shaft can be adjusted by adjusting nut, and the axial clearance of the second, third and fourth shaft can be adjusted by adjusting pad. 4. Sprocket: The sprocket and half drum are integrated to transmit power to the scraper chain. 5. Headstock: The headstock is assembled by welding the side plate and the bottom plate, and its side is used to fix the reducer and the blind shaft assembly, and the tail end is connected to the transition groove. 6. Blind shaft: Blind shaft is composed of bearing seat, blind shaft and other parts. Its main function is to support the sprocket. 7. Chain tensioner: The chain tensioner is composed of eccentric wheel, shell, brake band, brake wheel and other parts. The brake band is used to hold the brake wheel to realize braking, and it is used in conjunction with the tight chain hook to play a tension scraper. The role of the plate chain. 8. Transition groove: The transition groove is formed by welding the groove steel and the middle plate, and it is the transition connection device of the headstock and the middle groove. 9. Middle groove: The middle groove is an important part of the scraper conveyor. It is formed by group welding of the groove steel, the middle plate, and the connecting pin. The middle groove and the middle groove are longitudinally connected by the connecting pin. 10. Scraper chain: The scraper chain is assembled by a ring chain, a scraper, a connecting ring, and bolts. The scraper material is rolled steel, and the side with the inclined surface is in contact with the middle slot plate to play coal scraping. Function, the convex part of the connecting ring plays a guiding role. 11. Tail: The tail is assembled by the tail frame and the tail shaft, which is the guide mechanism for the rotation of the scraper chain. It is also possible to use a double drive method, that is, the head and tail are both transmission parts, which can increase the laying length of the whole machine to 160m. Note: When using dual drive mode, only one set of electronic control device can be shared. Turn the head and tail transmissions to the same direction before turning on the power. Otherwise, accidents such as breaking the scraper chain or damaging the transmission will occur. 12. Left and right baffles: Scraper conveyors are generally not equipped with left and right baffles when they leave the factory. If the user needs, special orders can be made.

Product Details

SGB420 / 40TX scraper conveyor is mainly used for conveying coal in the coal mining face of the gently inclined thin coal seam and the Central Plains coal seam below the coal mine. This product has the characteristics of strong transportation, stable transmission, simple structure, convenient assembly and disassembly, easy maintenance, safety and reliability. Its type, size and main technical performance are in accordance with MT / T105-93 "Types and parameters of mining scraper conveying models. "Provisions. It can be equipped with double transmission according to requirements, that is, the scraper uses two 40KW motors and two JS40 reducers. The maximum laying length can reach 160m, which greatly improves the transportation volume compared with 30 scrapers.

Structure and performance of main parts

1. Overall structure: This product is mainly composed of transmission parts, moving beams, transition grooves, middle grooves, scraper chains, tails, left and right baffles and other components.

2. The main component structure and working principle

Transmission part: The transmission part is mainly composed of motor, reducer, sprocket, headstock, tongue plate, blind shaft, chain tensioner and other components. The coupling cover connects the motor and reducer into a whole, and the power is transmitted to the The sprocket and sprocket drive the scraper to form a closed stepless transmission chain, which plays the role of transporting coal.

3. Reducer: The reducer is a three-stage conical cylindrical gear transmission with a transmission power of 40kw and a transmission ratio of 24.564. In order to ensure the normal operation of the bearing, the axial clearance of the bearing should be appropriately adjusted: the *** axis is 0.04--0.1; the second axis is 0.08-0.15; the third axis is 0.07-0.15; the fourth axis is 0.2-0.4 The axial position of the arc bevel gear should also be adjusted appropriately to ensure a reasonable meshing backlash and contact spots. The meshing backlash is not less than 0.17mm, and the contact spots are not less than 50% in the direction of tooth length and tooth height. *** The axial clearance of the shaft can be adjusted by adjusting nut, and the axial clearance of the second, third and fourth shaft can be adjusted by adjusting pad.

4. Sprocket: The sprocket and half drum are integrated to transmit power to the scraper chain.

5. Headstock: The headstock is assembled by welding the side plate and the bottom plate, and its side is used to fix the reducer and the blind shaft assembly, and the tail end is connected to the transition groove.

6. Blind shaft: Blind shaft is composed of bearing seat, blind shaft and other parts. Its main function is to support the sprocket.

7. Chain tensioner: The chain tensioner is composed of eccentric wheel, shell, brake band, brake wheel and other parts. The brake band is used to hold the brake wheel to realize braking, and it is used in conjunction with the tight chain hook to play a tension scraper. The role of the plate chain.

8. Transition groove: The transition groove is formed by welding the groove steel and the middle plate, and it is the transition connection device of the headstock and the middle groove.

9. Middle groove: The middle groove is an important part of the scraper conveyor. It is formed by group welding of the groove steel, the middle plate, and the connecting pin. The middle groove and the middle groove are longitudinally connected by the connecting pin.

10. Scraper chain: The scraper chain is assembled by a ring chain, a scraper, a connecting ring, and bolts. The scraper material is rolled steel, and the side with the inclined surface is in contact with the middle slot plate to play coal scraping. Function, the convex part of the connecting ring plays a guiding role.

11. Tail: The tail is assembled by the tail frame and the tail shaft, which is the guide mechanism for the rotation of the scraper chain. It is also possible to use a double drive method, that is, the head and tail are both transmission parts, which can increase the laying length of the whole machine to 160m.

Note: When using dual drive mode, only one set of electronic control device can be shared. Turn the head and tail transmissions to the same direction before turning on the power. Otherwise, accidents such as breaking the scraper chain or damaging the transmission will occur.

12. Left and right baffles: Scraper conveyors are generally not equipped with left and right baffles when they leave the factory. If the user needs, special orders can be made.

- Prev:Null