Various types of scrapers, scraper conveyors, scraper conveyors, coal runners used in coal mines

- Brief introduction: Scraper conveyor Scraper conveyor, also called scraper, coal skimmer, is an important conveying equipment for coal mine underground. It is used in conjunction with the scraper transfer machine and belt conveyor for the flute to play the role of transporting coal. According to the production host manufacturers, it can be divided into: Zhangjiakou coal scraper conveyor, Shandong mining machine scraper conveyor, northwest Benniu scraper conveyor, Shanxi coal machine factory scraper conveyor, Zheng coal machine scraper conveyor, Lin State Heavy Machinery Scraper Conveyor, Sany Heavy Industry Scraper Conveyor, etc .; According to the model of scraper, it can be divided into: SGD320 / 17B, SGD420 / 22, SGB420 / 30, SGB420 / 40TX (small 40), SGB620 / 40T (large 40), SGB630 / 150C, SGZ630 / 220, SGZ630 / 264, SGZ730 / 400, SGZ764 / 400, SGZ764 / 500 and other models. According to the chain wheel and chain of scraper, it can be divided into: medium single chain scraper conveyor, medium double chain scraper conveyor, side double chain scraper conveyor; Modified scraper conveyor SGZ double-chain scraper can be used between general mining and fully mechanized mining scraper, or it can be used for fully mechanized mining scraper. The 40T modified double-chain scraper is based on the SGB620 / 40T (large 40) scraper. By replacing the ordinary scraper steel scraper with a forged scraper, the B-level chain and chain link Replace with C-level chain and chain link, and replace the head wheel and tail wheel assembly with the head wheel and tail wheel in the form of a double-chain. 150 double chain scraper is modified on the basis of SGB630 / 150C type scraper. Similarly, by replacing the ordinary scraper steel scraper with a forged scraper, the B-level chain and chain link are replaced with C The process of replacing the head wheel and tail wheel assembly with the middle double-chain form of the head wheel and tail wheel of the high-grade chain and chain link improves the service life of the wearing parts and reduces the frequency and time of replacement parts.

Product Details

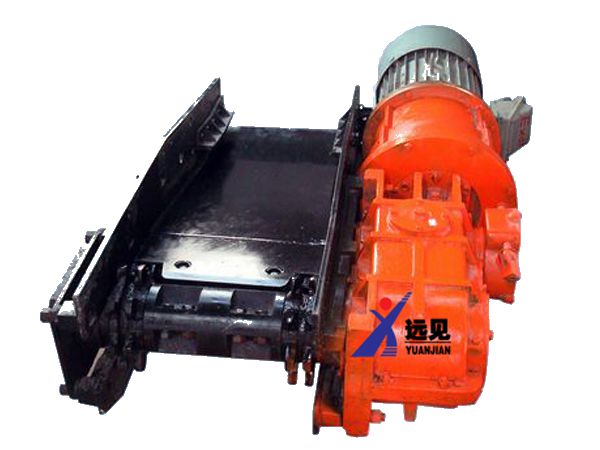

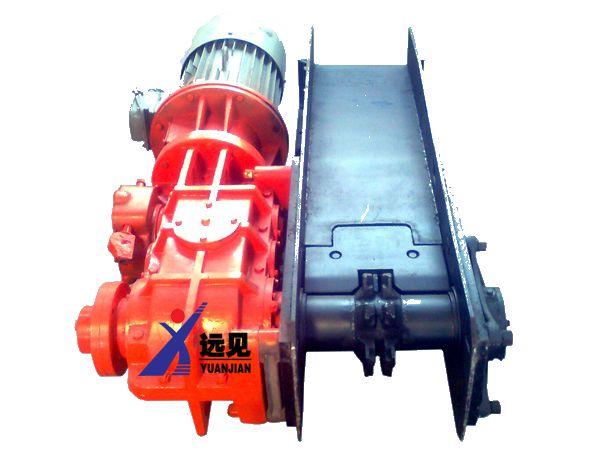

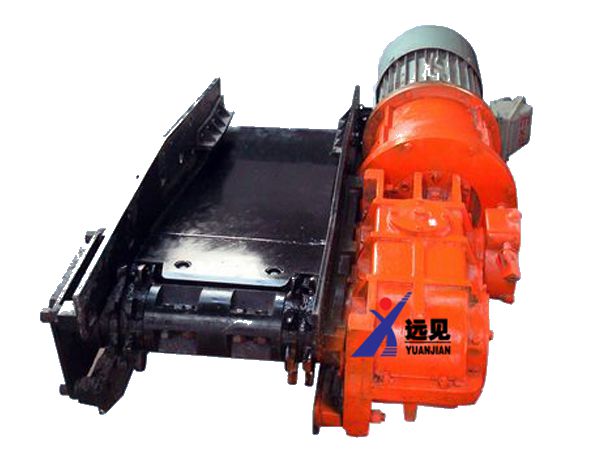

Scraper conveyor

Scraper conveyor, also called scraper, coal skimmer, is an important conveying equipment for coal mine underground. It is used in conjunction with the scraper transfer machine and belt conveyor for the flute to play the role of transporting coal.

According to the production host manufacturers, it can be divided into: Zhangjiakou coal scraper conveyor, Shandong mining machine scraper conveyor, northwest Benniu scraper conveyor, Shanxi coal machine factory scraper conveyor, Zheng coal machine scraper conveyor, Lin State Heavy Machinery Scraper Conveyor, Sany Heavy Industry Scraper Conveyor, etc .;

According to the model of scraper, it can be divided into: SGD320 / 17B, SGD420 / 22, SGB420 / 30, SGB420 / 40TX (small 40), SGB620 / 40T (large 40), SGB630 / 150C, SGZ630 / 220, SGZ630 / 264, SGZ730 / 400, SGZ764 / 400, SGZ764 / 500 and other models.

According to the chain wheel and chain of scraper, it can be divided into: medium single chain scraper conveyor, medium double chain scraper conveyor, side double chain scraper conveyor;

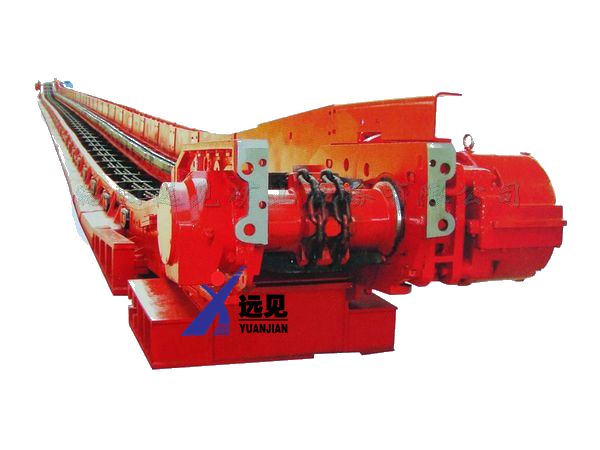

Modified scraper conveyor

SGZ double-chain scraper can be used between general mining and fully mechanized mining scraper, or it can be used for fully mechanized mining scraper.

The 40T modified double-chain scraper is based on the SGB620 / 40T (large 40) scraper. By replacing the ordinary scraper steel scraper with a forged scraper, the B-level chain and chain link Replace with C-level chain and chain link, and replace the head wheel and tail wheel assembly with the head wheel and tail wheel in the form of a double-chain.

150 double chain scraper is modified on the basis of SGB630 / 150C type scraper. Similarly, by replacing the ordinary scraper steel scraper with a forged scraper, the B-level chain and chain link are replaced with C The process of replacing the head wheel and tail wheel assembly with the middle double-chain form of the head wheel and tail wheel of the high-grade chain and chain link improves the service life of the wearing parts and reduces the frequency and time of replacement parts.