Wonderful review! Luoyang Vision held a lean management knowledge sharing exchange on May 30

Time:2019-05-31 Click:816

In order to improve the on-site management of 6S, keep improving production.

Luoyang Yuanjian Mine Equipment Co., Ltd. regularly

Organize team leaders and cadres and above

Lean management knowledge sharing and exchange meeting.

Exchange and share theoretical and practical management experience,

Continuously improve the company's management level, product quality and production efficiency!

The theme of this meeting is around timely delivery.

Driven by the sharer Zhao Zhibin,

Luoyang foresighted people to discuss in depth

The feasibility and necessity of "on time" production system construction,

And how to ensure on-time delivery from the management level.

Let ’s review the exciting content together:

At the sharing meeting,

In response to the problems and confusion that companies face in product delivery,

Such as external market constraints, unreasonable production plans,

There are many abnormalities in production management and control, as well as weak logistics.

Sharers elicit targeted countermeasures

——JIT production system.

From production planning, resource allocation, logistics management,

Improve the lean management level in four aspects of the guarantee system,

This in turn ensures that products are produced efficiently and delivered on time.

Guiding ideology: only when needed, the quantity needed for production and handling,

The required products realize the best production time (JUST—IN—TIME).

In terms of production, the sharer put forward the "kanban system" proposal.

Realize the transmission of production information one by one by Kanban;

The order of placing Kanban is the production order;

Realize the monitoring of plan execution power through kanban delivery;

Change the plan with kanban to achieve flexible response to plan changes;

It can be said to achieve precise control of digital production,

It is conducive to ensuring that products are delivered on time.

"Goods store" lean logistics

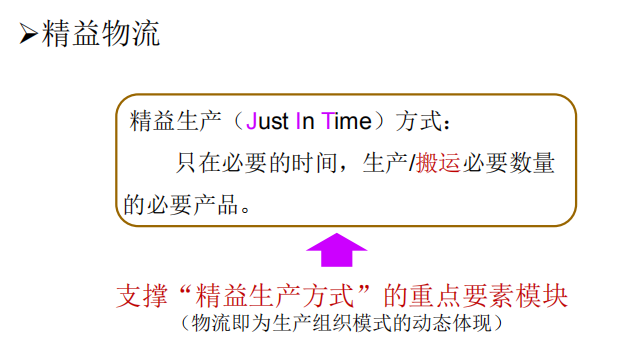

Regarding logistics, the sharer put forward the concept of "lean logistics".

Lean logistics: produce / handle the necessary quantity of necessary products only at the necessary time.

And establish a unit product "goods store".

Generate safety inventory through the goods store to obtain the adjustment of the production schedule.

Can also monitor the production progress and plan changes through the store;

Effectively shorten the logistics distance and transshipment and abnormal feedback;

Improve logistics management efficiency and ensure on-time delivery.

Lean concept of "shorten manufacturing cycle"

The manufacturing cycle generally includes: waiting for processing time, production change time,

Processing time, waiting transfer time, transfer time, etc.

Shorten the manufacturing cycle to improve production efficiency,

Meet customer needs in a short time.

The main method for sharing people to shorten the cycle is

From batch transfer to single transfer.

Realize "simultaneous" production of equipment,

Optimize process flow and production line,

Promote "standard operations" within the team.

To improve work efficiency and reduce labor intensity.

Lean management improves security capabilities

Lean management means refined management,

Mainly to clarify the elements of on-site management.

Mainly include personnel, equipment, cost,

Safety, quality, environment, etc.

Involves production schedule management, personnel operation management,

Man-hour efficiency management, production exception management,

WIP storage management, performance index management

On-site quality management, manufacturing cost management,

On-site safety management and other comprehensive guarantee systems.

From the lean management knowledge sharing exchange meeting,

It can be seen that Luoyang's vision is determined to implement 6S management,

And the efforts to grasp production and management,

Luoyang foresight people are good at communication, willing to communicate and share,

"Stones from other mountains can attack jade, learn from each other's strengths"

Only in this way can we continuously improve ourselves,

I believe in every such effort,

One step closer to the established goal,

Can go further from success!