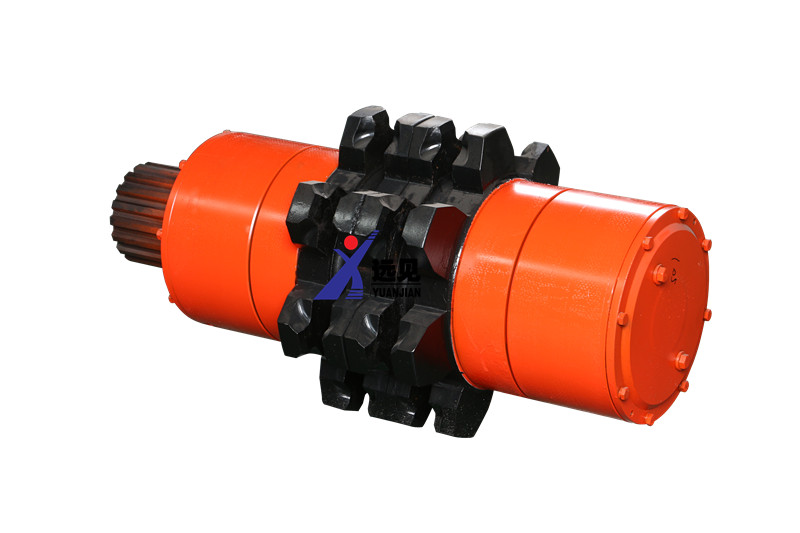

155S800304 sprocket shaft group

- Brief introduction: Main parameters of 155S800304 type sprocket shaft group The main technical parameters are: total length 900mm, height at both ends 245mm, the distance between two positioning holes is 570mm. The sprocket body is made of 5 teeth 42CrMo forged heat-treated sprocket. The outer diameter of the sprocket is 443mm. The middle double-chain sprocket is equipped with 34 × 126 grade C heat-treated chain. The fully mechanized sprocket shaft group is generally composed of sprocket , sprocket shaft, bearing, bearing seat , sealing ring and other parts. The sprocket shaft group, also called sprocket assembly, is suitable for scraper conveyors for underground coal mines and scraper transfer machines for flutes. According to the use position, it can be divided into: machine head sprocket shaft group and machine tail sprocket shaft group. According to the supporting main engine factory, it can be divided into: Zhangjiakou coal machine sprocket shaft group, Shandong mining machine sprocket shaft group, northwest Benniu sprocket shaft group, Shanxi coal machine factory sprocket shaft group, Zheng coal machine sprocket shaft group, Huainan long wall sprocket shaft group , Linzhou Heavy Machinery sprocket shaft group, Sany Heavy Industry sprocket shaft group, etc. According to applicable models, it can be divided into: 630, 730, 764, 800, 830, 900, 1000, 1200, 1250, 1400 and other models. The sprocket assembly is mounted on the head frame and tail frame of the head drive section, and is mainly composed of an end cover, a bearing seat, a sprocket body, a shaft, a floating seal ring assembly, a rolling bearing and a roller, etc. The sprocket is a forged seven-tooth sprocket made of alloy steel, processed and formed by the machining center, and the tooth surface is quenched. After the sprocket assembly has been running for 6 months, it is installed after being turned 180 °, so that both sides of the sprocket teeth are evenly worn.

Product Details

Main parameters of 155S800304 type sprocket shaft group The main technical parameters are: total length 900mm, height at both ends 245mm, the distance between two positioning holes is 570mm. The sprocket body is made of 5 teeth 42CrMo forged heat-treated sprocket. The outer diameter of the sprocket is 443mm. The middle double-chain sprocket is equipped with 34 × 126 grade C heat-treated chain. The fully mechanized sprocket shaft group is generally composed of

sprocket , sprocket shaft, bearing, bearing seat , sealing ring and other parts.

The sprocket shaft group, also called sprocket assembly, is suitable for scraper conveyors for underground coal mines and scraper transfer machines for flutes.

According to the use position, it can be divided into: machine head sprocket shaft group and machine tail sprocket shaft group.

According to the supporting main engine factory, it can be divided into: Zhangjiakou coal machine sprocket shaft group, Shandong mining machine sprocket shaft group, northwest Benniu sprocket shaft group, Shanxi coal machine factory sprocket shaft group, Zheng coal machine sprocket shaft group, Huainan long wall sprocket shaft group , Linzhou Heavy Machinery sprocket shaft group, Sany Heavy Industry sprocket shaft group, etc.

According to applicable models, it can be divided into: 630, 730, 764, 800, 830, 900, 1000, 1200, 1250, 1400 and other models.

The sprocket assembly is mounted on the head frame and tail frame of the head drive section, and is mainly composed of an end cover, a bearing seat, a sprocket body, a shaft, a floating seal ring assembly, a rolling bearing and a roller, etc. The sprocket is a forged seven-tooth sprocket made of alloy steel, processed and formed by the machining center, and the tooth surface is quenched. After the sprocket assembly has been running for 6 months, it is installed after being turned 180 °, so that both sides of the sprocket teeth are evenly worn.

- Next:Sprocket body