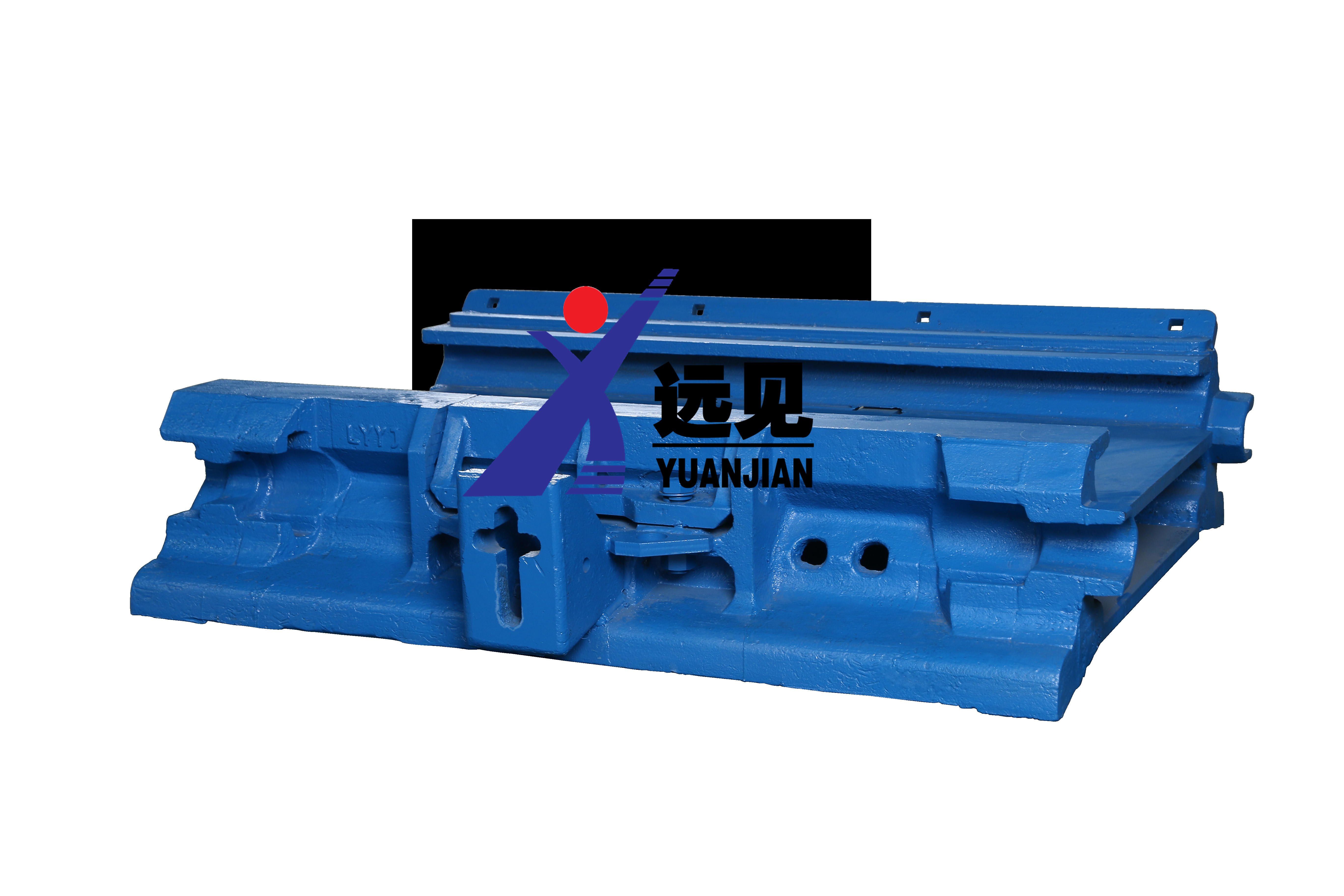

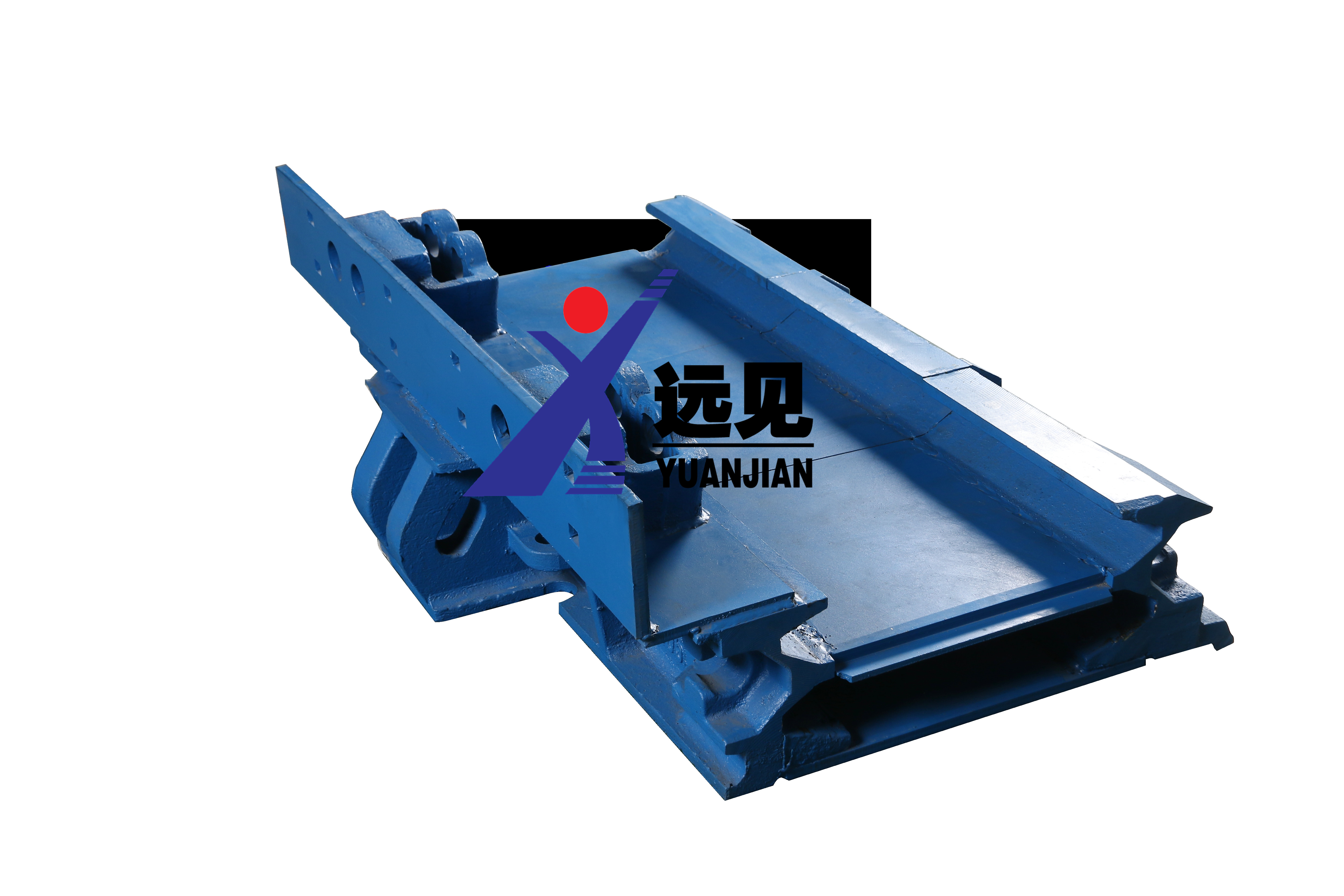

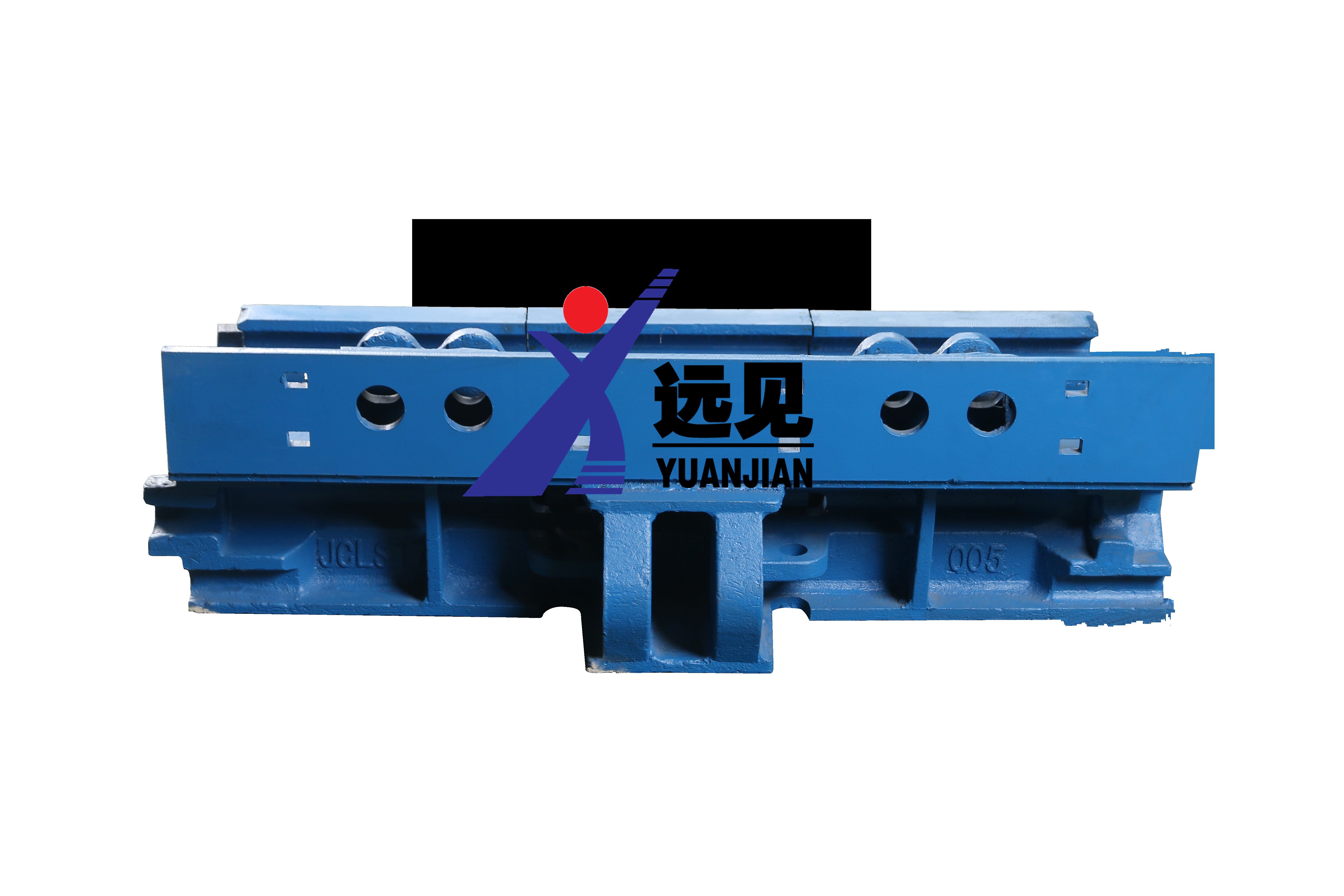

30 middle trough, 30 scraper middle trough, SGB420 / 30 middle trough, 30 chute

- Brief introduction: The central trough is one of the main components of the product and is the channel for coal transportation. The central groove steel is cold pressed groove steel or rolled groove steel. The middle groove composed of cold pressed groove steel is welded by 8mm thickcold pressed groove steel and 6mm thick middle plate. The middle groove composed of rolled groove steel is welded by an 8mm thick rolled groove and a 6mm thick middle plate, and the length is 1200mm . A connecting pin is welded at one end of the groove, and the connecting pin is inserted into the groove of the adjacent middle groove to realize mutual positioning. The middle groove can be offset by 3 ° in the horizontal plane to meet the needs of the undulation of the working floor and the overall movement of the machine. The position of the middle plate chain is carbon arc surfacing 1.5 to 2mm thick wear-resistant alloy to increase wear resistance and improve service life. According to requirements, the support of the coal fender can be welded on the middle groove of each section, and the coal fender can be installed to increase the conveying capacity.

Product Details

The central trough is one of the main components of the product and is the channel for coal transportation. The central groove steel is cold pressed groove steel or rolled groove steel. The middle groove composed of cold pressed groove steel is welded by 8mm thickcold pressed groove steel and 6mm thick middle plate. The middle groove composed of rolled groove steel is welded by an 8mm thick rolled groove and a 6mm thick middle plate, and the length is 1200mm . A connecting pin is welded at one end of the groove, and the connecting pin is inserted into the groove of the adjacent middle groove to realize mutual positioning. The middle groove can be offset by 3 ° in the horizontal plane to meet the needs of the undulation of the working floor and the overall movement of the machine. The position of the middle plate chain is carbon arc surfacing 1.5 to 2mm thick wear-resistant alloy to increase wear resistance and improve service life. According to requirements, the support of the coal fender can be welded on the middle groove of each section, and the coal fender can be installed to increase the conveying capacity.

- Next:40 central groove