How to improve the abrasion resistance of the middle groove of the scraper?

Time:2020-03-24 Click:860

Three methods to teach you to reduce the wear of the middle groove of the scraper conveyor

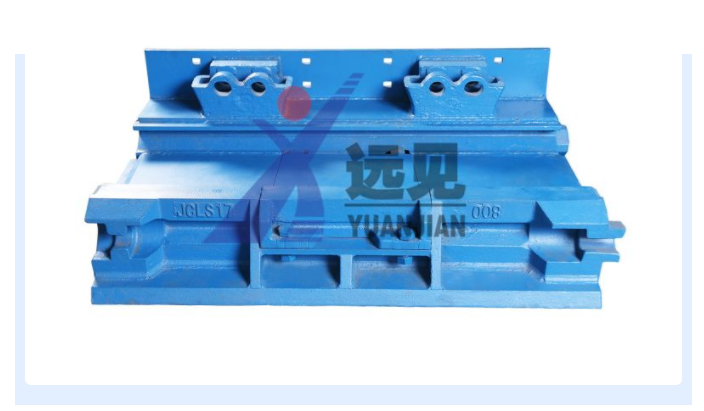

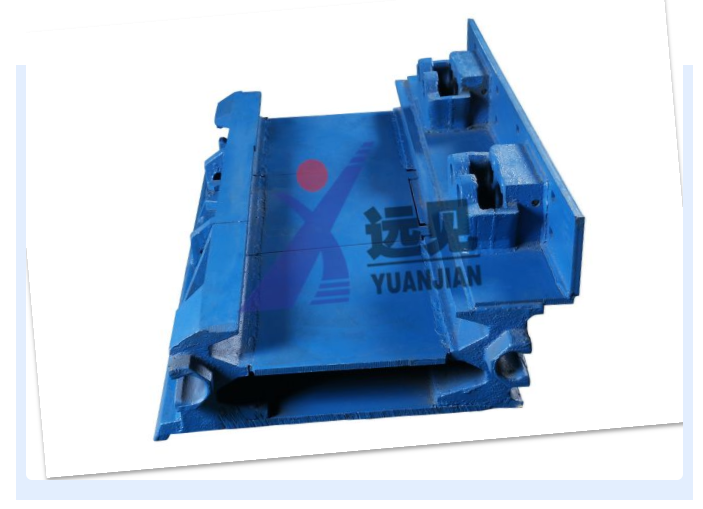

The middle groove of the scraper conveyor is affected by factors such as the complex environment of the coal mine and its own design limitations, and is very prone to wear. If the wear of the middle groove of the scraper conveyor is not solved in time, it will seriously affect the transport capacity of the scraper conveyor and even affect the production of the coal mine. Luoyang Foresight today teaches you three ways to reduce the wear of the central groove.

Proper operation and maintenance

Improving the quality of personnel can effectively reduce the wear failure of the central groove of the scraper conveyor. Coal mining companies should provide technical training to the operators of the scraper conveyor, for example: the idler is prohibited from idling when there is no material to carry, reducing unnecessary energy consumption and wear; keep the work surface flat and straight before starting the scraper conveyor, Prevent the two scraper chains from wearing unevenly and wear; the middle slot and scraper chain should not be overloaded or run for too long at one time, otherwise fatigue and wear will occur.

Reasonable selection of wear-resistant materials

At present, the material of the central groove of the scraper conveyor in China is mostly 16Mn steel, and the wear resistance of this material is still a certain gap compared with the alloy steel of advanced foreign countries. Choose low-friction, anti-friction materials. In addition, the correct heat treatment process can also increase its abrasion resistance. Coal mining companies should choose powerful manufacturers and carefully consider their manufacturing processes when purchasing central tanks. Luoyang has seen 24 years of coal machinery equipment experts, and its products are trustworthy.

Surface coating technology

A surface coating is a thin film of one or more layers of material applied to a solid surface to strengthen the surface. Common coating methods include surfacing and thermal spraying. When selecting the middle slot of the scraper conveyor to apply the coating, the coating material should be selected according to the work conditions and coating properties of the workpiece. A coal mine enterprise can reach a cooperative relationship with a manufacturer. When the surface of the middle groove is severely worn, it is quickly sent to the manufacturer for surface treatment to prevent its wear from rapidly deteriorating.

The middle groove of the scraper conveyor can effectively reduce the wear through reasonable design, material selection and heat treatment. Coal mining enterprises must choose a strong manufacturer when purchasing the central slot of the scraper conveyor, comprehensively review the production process, especially the above process, and then purchase. Luoyang Yuanjian Mining Equipment Co., Ltd. was established in 1996. It has rich production experience and complete technology. The quality of the mining equipment such as the scraper parts produced is excellent.

- Prev:Null