How to commission and install the scraper conveyor

Time:2019-12-10 Click:352

One.Preparations before installing the scraper conveyor

(1)The staff participating in the installation and commissioning should carefully read the manual of the machine,the instructions of the supporting equipment and other relevant technical information and safety regulations,and be familiar with the structure,working principle,installation procedures and precautions of the machine;

(2)Check whether the form and capacity of the scraper conveyor are suitable for the working conditions;

(3)Check all parts,accessories,spare parts and special tools of the whole machine item by item according to the factory delivery list and technical information of the machine;

(4)According to the technical information provided by the whole machine,inspect the appearance quality and geometric shape of all parts and components,and repair and remove rust if there are injuries,deformations and rusts.Especially for explosion-proof equipment,it must be inspected by a full-time explosion-proof inspector,and a well must be issued before it can go down;

(5)Prepare installation tools and grease;

(6)Designate work command personnel and select the installation site.

In order to check the mechanical performance of the scraper conveyor,so that the installation and maintenance and operating personnel are proficient in the installation,repair and operation techniques,it is best to install and debug on the ground,and think that there is no problem before installing it in the well.

two.Interview installation requirements for scraper conveyor

(1)The machine head must be placed properly,and the stability pad does not shake;

(2)The laying of the central chute must be flat,stable,and straight,and the laying direction must be correct,that is,the deck of each section must face the nose;

(3)There must be a tight and tight gap between the coal blocking board and the groove;

(4)A scraper conveyor with a coal shovel board,the coal shovel board and the trough should be tight and close to each other;

(5)The welded joints of the circular chain shall not face the middle plate and shall not be tightened;the number of links in each section between the double chain scrapers must be equal.The direction of the scraper must not be wrong.The bolt connected to the scraper in the horizontal direction must have the head facing the running direction.The bolt connected to the scraper in the vertical direction must have the head toward the middle plate.

(6)The signal device installed along the scraper conveyor must meet the requirements;

(7)Careful inspection and trial operation should be performed after installation.Only after the operation is normal can preparations be made before installation in the well.

three.Procedure when installing scraper conveyor on the ground

(1)All installation personnel should always observe the safety operation regulations,strictly prevent the occurrence of equipment and personal accidents,and draw up the installation process documents;

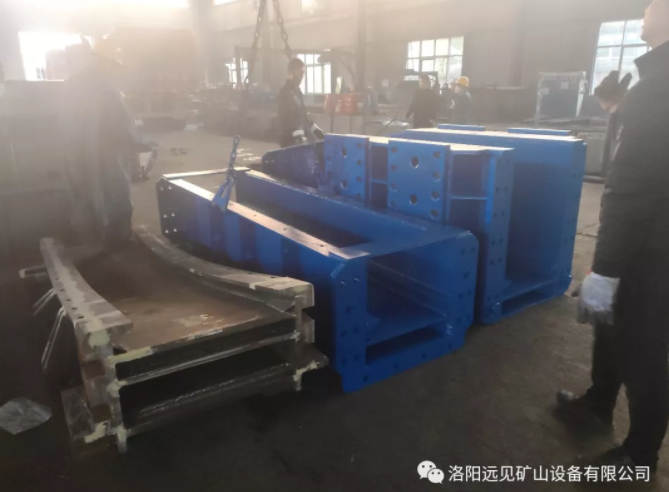

(2)Ship all the parts for installation to the installation site and discharge them neatly according to the intended installation position;

(3)First install and fix the machine heads together,and connect the power supply to the motor as required;

(4)Pass the scraper chain through the lower chain of the headstock.The chains cannot be twisted or twisted with each other.The round chain welding joint is on the lower side;

(5)Install the tail part in a similar way,and connect the chain with quick joints in order to reach a sufficient length;

(6)Pass the chain around the head and tail sprocket respectively and connect them on the upper chain,and keep it loose;

(7)Install the remaining parts and components according to the general drawing of the equipment;

(8)Remove the sundries at the chain and check whether the connection and fastening of each part is reliable.

four.Precautions for no-load test run on the ground

(1)Jog the motor and observe whether the head and tail motors turn correctly.After the directions are the same,then turn on the motor and observe for scratches and abnormal sounds;

(2)The motor driven by the tail should be ahead of the motor driven by the nose.Generally,it should be controlled between 0.0035 and 0.013s/m.The accumulated time is the delay time,but the minimum leading time is not less than 0.5s.,***Large lead time is not greater than 3s;

(3)Start the scraper conveyor,check the motor and reducer for abnormal noise,and the temperature should not rise suddenly;

(4)Whether the mesh between the chain and the sprocket is normal,and whether there is a chain skipping phenomenon.Whether the scraper chain has a beating phenomenon during the transition of the machine head or the middle section.If it is jumping,it indicates that the chain pretension is too large,and the pretension should be reduced again;

(5)The scraper chain should be free of jams throughout the entire chain.

Fives.Preparation of buried scraper conveyor before going down the well

(1)All parts should be intact,otherwise repair should be performed;

(2)It is not necessary to disassemble the parts that go down the well,and the couplings and fasteners should be fastened reliably;

(3)The parts that need to be decomposed into the well shall be placed according to categories and marked.Small parts that are volatile and miscible shall be packed according to categories.Exposed processing and matching components(such as shaft holes,oil holes,etc.)shall be taken Prevent bumps,blockages,and dirt;

(4)According to the installation situation on the ground,formulate the downhole and downhole installation process,and mark the delivery location after the downhole at the obvious position of the downhole machinery.

six.Precautions for underground installation and commissioning of scraper conveyor

(1)The installation and commissioning of the scraper conveyor in the underground can be performed with reference to the order of surface installation and commissioning;

(2)It is installed along the bottom of the well to avoid the accumulation of mechanical parts in the upper and lower grooves;

(3)Lay the scraper conveyor as straight as possible to ensure its reliability and life;

(4)Perform no-load operation for 1 to 2 hours,and the operating conditions should meet the requirements;

(5)Perform multi-machine linkage load operation for 4h and check the following:

①Tighten all parts without loosening;

②The tightness of the two scraper chains is basically the same;

③The temperature of the motor,reducer,sprocket shaft and other parts must not exceed the allowed value of 75°C;

④The electrical system works normally;

⑤Tighten the chain again.When the tightness is full according to the specified laying length,it is advisable to loosen the two chain links below the machine head,otherwise the chain needs to be tightened again.After all parts are debugged normally,they can be put into normal use.

Seven.Installation requirements of scraper conveyor in fully mechanized mining face

(1)The tail of the scraper conveyor in a fully mechanized mining face is generally installed after the coal mining machine rides on the chute.Because the tailstock is high,installing the tailstock first increases the workload of installing the shearer;

(2)Install the coal fender after installing the middle tank.If the central slot is close to the coal gang and there are floating coals that hinder the installation of the shovel board,you can install the shovel board after the cutter cuts a knife,but the L-type shovel board must be installed before the coal cutter;

(3)The installation of the central groove is generally performed in cooperation with the installation of the hydraulic support.The central groove can be installed first and then the bracket,or the central groove can be installed while the bracket is installed to ensure the distance between the brackets.If the bracket is installed first and then the middle groove,the bracket spacing must be adjusted in time to avoid the inconsistency between the bracket and the middle groove and affect the connection of the pushing jack;

(4)When a monorail crane is used to install a hydraulic support in cooperation with a slide plate provided in the middle slot,all working surface scraper conveyors must be installed first,then the scraper conveyor is started,and the slide plate with the bracket is transported by the scraper chain Go to the bracket installation site.This method of installing the scraper conveyor first can not only ensure the distance between the supports,but also clean up the floating coal on the working surface at any time.

Eight.Installation requirements of working surface scraper conveyor head

(1)The position of the machine head must meet the requirements of the design position.It must be able to unload coal smoothly and ensure proper connection with the hydraulic support;

(2)The machine head must be positioned correctly.When using single or double traction,the driving device should be installed on the side of the goaf,and there should be a distance of not less than 700m m from the goaf pillars for pedestrians and maintenance;

(3)The connecting bolts of the reducer and the machine head must be fully installed and fastened.Do not install fewer bolts due to poor installation conditions;

(4)The machine head should be stable and the pad should not be shaken.If necessary,it should be fixed on the top beam of the machine head with a pillar.Do not support the pillar on the reducer or the head frame.

nine.Installation requirements for the central groove of the working surface scraper conveyor

(1)The laying of the central groove should be flat,straight and stable.If there are coal blocks or vermiculite on the floor,it must be removed before laying.In order to ensure the flatness and straightness of the central slot,the miner's lamp can be used at both ends for comparison and correction by light;

(2)The laying direction of the central groove shall be from the nose to the tail;

(3)The laying direction of each middle slot must be correct,that is,the lap plate of each slot must be toward the tail of the machine to ensure that the back-to-back chain runs smoothly and does not cause scratches.

ten.The requirements of the tight chain after the buried scraper conveyor is installed and in use are as follows:

(1)During the initial operation of the scraper conveyor,the gap between adjacent chute joints tends to be closer,and the gap is reduced;

(2)Plastic deformation and wear during the use of the scraper chain;

(3)The scraper chain is stretched by the drag chain during operation,resulting in elastic elongation.

Due to the above three situations,the scraper chain will be extended.The elongated scraper chain will loosely accumulate in the place where the tension is the smallest,resulting in accidents such as dropped chains,skipped chains or broken chains.In order to ensure the safe operation of the scraper conveyor and prevent these accidents,it is necessary to tighten the elongated and loosened scraper chain at any time.

eleven.Commissioning of buried scraper conveyor

1.Precautions during the trial operation of the scraper conveyor After the scraper conveyor is installed,you should further check whether the components are installed correctly,whether the bolts are firm,and whether the lubrication system oil is sufficient,and then perform no-load experiments.

2.Jog intermittently at the beginning,start and stop trial operation.First check whether the running direction of the upper and lower heads is correct;then turn on and stop the trial operation to check whether each part is scratched.After the squeegee chain has been rotated for 1 or 2 cycles,carefully check whether the parts of the squeegee chain are connected correctly and add the missing squeegee;then run it idle for 10 to 15 minutes,and then further check the condition of each part,if necessary,tighten the squeegee chain again..

3.After confirming that there is no problem during dry running,you can run with load.In order to ensure the tightening of each bolt,all bolts and nuts should be tightened again after one shift.

Luoyang Yuanjian Mining Equipment Co.,Ltd.was founded in 1996.It integrates production and sales,has strong technical force,advanced processing technology and strict management system.The products of various product models such as scraper conveyor and reducer have obtained the mining safety certificate.We use the quality structure to bridge between us.Welcome to consult and order.