How to improve the abrasion resistance of the middle groove of the scraper?

Published:2020-03-21Author:Click:1260

The abrasion of the middle groove of the scraper is mainly the abrasion of the middle and the groove side, especially the wear of the joint of the two sections is more. Aiming at the cause of the failure of the central groove of the scraper, improvement measures are proposed, which can not only reduce the wear on the central groove, but also reduce the wear of the scraper conveyor accessories.

The improvement measures of the middle groove of the scraper can be considered from the following aspects:

Point 1

Made of high-strength wear-resistant material

At present, the common material for scraper conveyors is high-manganese steel. The strength and wear resistance of high-manganese steel are relatively good, but this material also has shortcomings. Faced with a complex underground operating environment, high manganese steel has poor corrosion resistance, is susceptible to rust, and has a short service life. Although high manganese steel has good wear resistance, it has a large friction coefficient and consumes a lot of energy. In order to improve the defects of the current central groove, a material with good abrasion resistance, low friction coefficient and corrosion resistance should be used. The main materials.

Point 2

Strengthening the surface of the central groove

Strengthening the chute surface can not only reduce the friction distance between the scraper and the chain in the middle groove, but also improve the service life of the middle groove. At present, high-manganese steel is used in the chute. In addition to changing the composition during the improvement process, it should also be strengthened. DRR-2 numerical control technology can be used to partially cover the surface of the central groove to enhance the wear resistance of the material. Strengthening the chute surface can not only reduce the friction distance between the scraper and the chain in the middle groove, but also improve the service life of the middle groove.

Point 3

Strengthen the maintenance management of scraper

In the management and maintenance of the scraper conveyor, first of all, before the installation, the inspection of the parts of the scraper conveyor should be done to ensure the quality of the machine parts. Second, during the installation process, the installation position of each component of the scraper conveyor should be determined. Each component should be installed straight, and the left and right staggers at the middle slot interface, headstock, tailstock and transition slot interface should be Less than 3mm. For excessively worn links, a new chain replacement should be used. When the chute is fully loaded, the amount of double chain sag of the head empty chain should be 60 ~ 140mm, and the single chain should be 30 ~ 100mm. Furthermore, in the process of pushing the scraper conveyor, it should be ensured that the distance between the curved part of the scraper conveyor and the shearer should be more than 16m, and the bending length should be greater than 13m. Accidents such as chain breaks due to misalignment of the chute. After Zui, after the installation is completed, it should be inspected in strict accordance with relevant standards, especially the fluid filling capacity check of the hydraulic coupler, which should be matched with the motor. In addition, the chute should be cleaned regularly to ensure that the chute working environment is clean.

Point 4

Do rust removal and surfacing work

Since the scraper conveyor is susceptible to rust, the rust removal work of the welding part should be done well. During the transportation of coal mines, the problem of abrasion is likely to occur on the coal crossing surface and the floor of the middle plate. To this end, the company should also do the overlay welding of two parts and use welding materials with better wear resistance to obtain better quality Grind the protective layer. After finishing the welding work, it should also do a good job of sanding to ensure the smooth passage of the coal scraper.

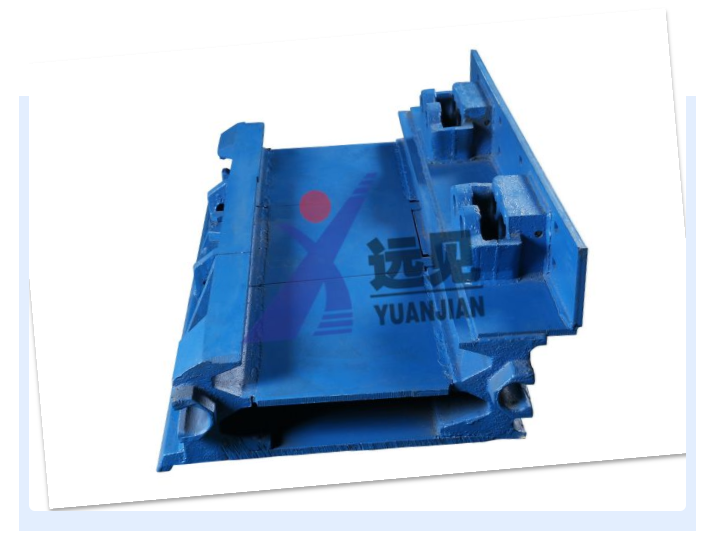

Coal mining enterprises should prolong the life of the central tank of the scraper from the aspects of purchase, installation and maintenance. Luoyang Yuanjian Mining Equipment Co., Ltd. was founded in 1996 and is a coal machine equipment expert with 24 years of experience. The company's scraper conveyors, scraper transferers and many other products have obtained national mining product safety mark certificates. The quality and safety of the products have been recognized, and the use of customers has been guaranteed. Regardless of technology and craftsmanship, they have absolute advantages in the same industry, and the business scope covers all major mining areas in the country. We are willing to cooperate wholeheartedly, develop together and create the future with your support. We use quality framework to build a bridge between us. Welcome everyone to consult and order.