"Secret" for wear resistance of scraper conveyor after surfacing repair

Published:2020-03-19Author:Click:2661

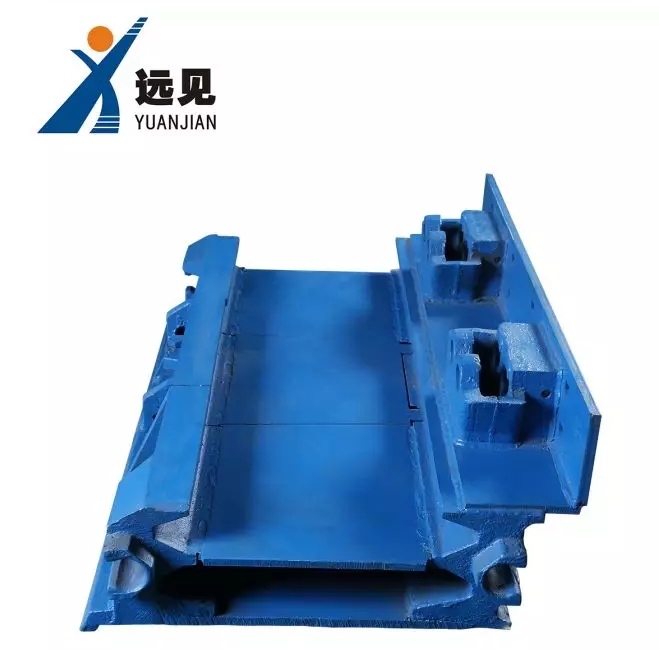

In order to save costs and achieve the goal of saving costs and reducing consumption, many coal mines usually repair and overlay the middle groove of the scraper conveyor with less severe wear. The following will reveal the "secret" of wear resistance after repairing the middle groove of the scraper conveyor.

Descaling and descaling process

Due to the adverse environmental conditions in the underground, the middle groove of the scraper conveyor will rust during the use in the coal mine. In order to reduce the impact of impurities during welding, the welding position of the middle groove of the scraper conveyor should be started before the welding process starts. Descaling is performed, and the middle groove of the unused scraper conveyor is protected by painting.

Surfacing process

Warm up

Because the overlay welding process requires temperature, in order to reach a certain temperature before the overlay welding, the construction site of the middle tank and the welding material must be heat treated.

2. base

Since the hardness of the central groove body is different from that of the wear-resistant material, if no bottoming measures are taken, the groove body and the wear-resistant layer are prone to delamination and fall off under stress. Therefore, it is necessary to adopt Overlay transition layer measures.

3. Insulation

After the priming process is performed, the required priming site needs to be insulated to maintain a certain welding temperature.

4. Wear-resistant treatment

Use the "self-fluxing alloy fusion surfacing method" to wear-resistant the wear parts of the chain, and fill the wear parts with the welding material; use the high-wear resistance welding material to the chute middle plate and the bottom plate scraper that are prone to wear problems Overlay welding is carried out to ensure that the site has a wear-resistant protective layer.

5. Polished

After the surfacing welding is completed, use an angle grinder to grind the slag on the surfacing area to ensure the normal operation of the scraper.

Through the above abrasion-resistant process, the service life of the middle groove of the scraper conveyor can be effectively extended, which is the "secret" of increasing the wear resistance of the middle groove after surfacing repair. Luoyang Yuanjian Mining Equipment Co., Ltd. produces various types of scraper accessories, reprinter accessories, etc. The products have higher wear resistance than the same industry, and the quality of the products is well-known. If necessary, you are welcome to come and buy.