23 years of coal machine equipment expert, take you to understand 100 cases of common knowledge of scraper conveyor

Published:2019-11-12Author:Click:2943

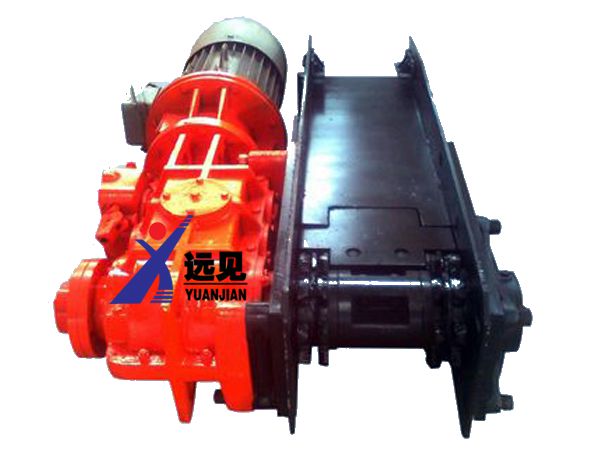

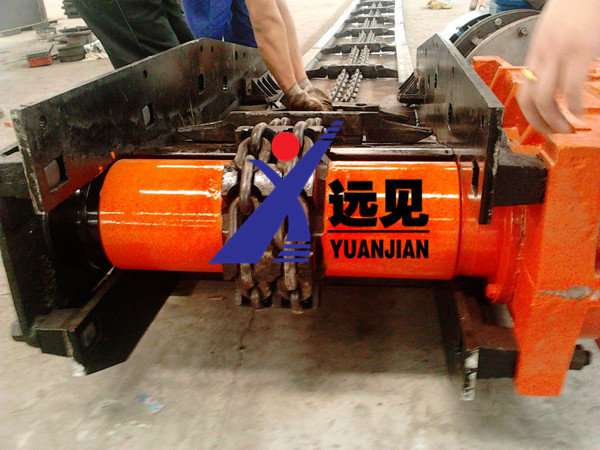

Luoyang Yuanjian Mine Equipment Co.,Ltd.was founded in 1996,with a plant area ofmore than 100 acres and more than 300 employees.It is a coal mine equipment manufacturing enterprise integrating production and sales.Based on strong technical force,advanced processing technology and strict management system,it has successively obtained mine safety mark certificates for various product models such as scraper conveyors and conveyor reducers in 2003.Today I will tell you about 100 cases of common knowledge of scraper conveyors.

1.It is mainly composed of the nose,middle and tail.

2.Scraper chain is divided into middle single chain,middle double chain,side double chain and quasi-edge double chain according to the arrangement.

3.Scraper conveyor can be used for horizontal transportation or inclined transportation.When transported along inclined transportation,the inclination angle of the coal seam should not exceed 25°,and when transported downward,the inclination angle should not exceed 20°.

4.The flexible scraper conveyor is allowed to bend 2°~4°in the horizontal and vertical directions to facilitate the use of the corresponding shearer and self-moving hydraulic support.

5.The transmission device includes a motor,a coupling,a reducer,and a main shaft.

6.Chute is the guide mechanism of the traction chain and cargo load of the scraper conveyor.

7.Chute can be divided into middle chute,regulating chute and connecting chute.

8.The protection device of the scraper conveyor has a protection pin protection device and a friction plate protection device.

9.The safety device of the scraper conveyor includes a chain break protection device,an overload protection device,a failure stop protection device,an anchor device to prevent the nose and tail from tipping over.

10.Common control switches for scraper conveyors are manual starter and magnetic starter.

11.The role of shoveling coal plate is to put the floating coal on the coal wall into the chute after passing through the chute.

12.The scraper conveyor at the working face must be equipped with a signal device that can send a stop or start along the entire length of the fuselage,and the distance between the signal points should not exceed 15m.

13.When the tandem conveyor is overlapped in a straight line,the background head should be higher than the front end 0.3m before and after 0.5m.

14.When the two scraper conveyors are connected in a straight line,the height of the unloading center should be kept at 0.3m,and when it is greater than 0.5m,a coal skid should be added.

15.When installing and putting into operation,keep the conveyor flat,straight,stable and firm,and pay attention to the tightness of the scraper chain.

16.The scraper conveyor cannot be forcibly started.If the scraper conveyor fails to start or cut off the safety pin three times in a row,the cause must be found and dealt with before restarting.

17.When stopping,the coal flow should be carried out in order from the inside to the outside,and the coal rock on the scraper conveyor should be pulled away.

18.“Four inspections”refers to shift inspection,daily inspection,weekly inspection and monthly inspection.

19."One perseverance"refers to perseverance in work positions.

20."Three achievements"refers to the neatness of equipment and environment,the absence of floating coal in the machine head,machine path and tail,and the realization of a civilized production environment.

21."Four diligence"refers to diligence in maintenance and inspection,diligence in inspection,diligence in handling oil injection problems,diligence in cleaning the head and tail coal storage pit.

22."Four strict"refers to strict implementation of operating procedures,strict on-site delivery,strict inspection system and strict compliance with labor discipline.

23.Itinerant inspection generally adopts methods such as seeing,touching,listening,sniffing,testing and measuring.

24.The number of inspections per tour should be no less than 2-3.

25.The melting point temperature of fusible alloy protection plug is generally 110~140℃.

26.The running time of the hydraulic coupling under braking conditions is generally not allowed to exceed 1min.

27.Bridge transfer machine is a kind of intermediate transfer transportation equipment commonly used in mining face.

28.When driving the roadway,the transfer machine can be used as a conveyor for the driving face and can be used in conjunction with the retractable belt conveyor to transport coal and gangue during the driving process.

29.The bridge transfer machine is composed of three parts:nose,fuselage and tail.

30.The effective lap length of the transfer machine and the retractable belt conveyor is 12m.

31.The signal must be sent before the transfer machine is started.After no one is working on or near the transfer machine,jog it and start it 2 or 3 times,then start it officially.

32.When the transfer machine is used in the coal roadway,the moving method can be moved by the winch traction,the horizontal oil cylinder of the hydraulic support and the specially-designed moving hydraulic cylinder.

33.The mobile machine in the mining face must cut off the power and open the clutch immediately after each shift and when the driver leaves the machine.

34.The crusher is mainly used to crush large pieces of coal and gangue to prevent damage to the conveyor belt and ensure the normal operation of the retractable belt conveyor.

35.Commonly used crusher types are cone crusher,jaw crusher and wheel crusher.

36.The driver of the crusher must pass the training and examinations and hold a certificate.

37.The crusher should be started under no-load conditions,the time of two jogs should not be less than 90s,and the number of continuous jogs should not exceed 5 times.

38.When handling large pieces of coal,rock and gangue on the transfer machine,the crusher should be blocked.

39.The crusher should check the operation of the sliding clutch 3 times a week to ensure safe operation.

40.When there is no centralized control system,the start of multiple scraper conveyors should start from the outside to the inside in the direction of the reverse coal flow.

41.When the scraper conveyor transports materials,there must be a special person to pick up the material at the transportation site.When two people move materials from the chute at the same time,the rear end should be moved first,and then the front end should be moved to avoid injury.

42.The maintenance content of the scraper conveyor includes the patrol inspection during operation to replace some wearing parts in time,adjust the scraper chain,tighten the bolts and strengthen the lubrication.

43 A special person must be appointed to maintain the fluid coupling and fill the working medium as required.

44.The working medium used in the fluid coupling is not allowed to be changed casually,only water medium or inflammable liquid is allowed.

45.If you need to change the melting point temperature of the fusible alloy,you must replace the protective plugs with different melting points.

46.When the two conveyors are overlapped and transported,the overlap length is not less than 500mm;the distance between the highest point of the nose and the highest point of the tail is not less than 300mm.

47.When the scraper conveyor and the belt conveyor are overlapped and transported,the overlap length and the height difference between the head and the tail are not greater than 500mm.

48.The fluid coupling has good transmission performance and protection function.

49.The use of a hydraulic coupling between the conveyor,the motor and the reducer can realize the motor light-load start or no-load start,the load starts gently,absorbs shock and eliminates torsional vibration,and realizes load balancing in multi-machine drive Protect the motor and the entire transmission system.

50.The fluid coupling observes the law of conservation of energy and the theorem of momentum.

51.The energy conversion process of the hydraulic coupling is the mechanical energy of the electric motor-the mechanical energy of the pump wheel-the kinetic energy of the working fluid-the mechanical energy of the turbine.

52.The hydraulic coupling is divided into static pressure liquid discharge type,dynamic pressure liquid discharge type and valve controlled extended filling type.

53.After the scraper conveyor stops,turn the magnetic start switch to zero position and lock it.

54.The coupling is the connection device between the motor and the reducer or the reducer and the main shaft of the machine head.Its main function is to transmit power and movement.

55.In order to prevent the conveyor from being overloaded,the general coupling is also used as a protection device when overloaded.

56.A reducer is a device used to change the number of motor revolutions and transmit motor torque.

57.The main shaft is the main component of the rotating device of the scraper conveyor,which drives the main chain wheel to draw the scraper chain.

58.The scraper chain is the traction mechanism of the scraper conveyor.

59.The chute is a guide mechanism for the traction chain and cargo load of the scraper conveyor.

60.The bearing of the scraper conveyor has good lubrication,no oil leakage,flexible rotation,and no abnormal noise.The temperature of the sliding bearing does not exceed 65°C,and the temperature of the rolling bearing does not exceed 75°C.

61.The rotation or transmission parts of the scraper conveyor should be provided with protective covers or protective railings;the tail of the machine should be covered;a bridge for people to cross the conveyor must be set up in an appropriate place.

62.Good lubrication can reduce the wear of machinery,and play a role in cooling,sealing,damping and anti-corrosion of components.

63.The basic structure of the reducer of the scraper conveyor can be divided into two types of vertical arrangement and parallel arrangement according to the direction of input and output.

64.The couplings used underground are mainly rigid and elastic.

65.When using torque-limiting hydraulic couplings,do not bring pulverized coal into the working chamber.

66.It is not allowed to change fusible alloy protective plugs with different melting points at will,and it is not allowed to use other materials to replace fusible alloy plugs and explosive protective plugs.

67.The fluid coupling should not start frequently with positive and negative loads to prevent the temperature of the working fluid from rising.

68.The elongation and deformation of the ring chain shall not exceed 3%of the designed length.

69.The layout of the chute of the scraper conveyor can be divided into parallel and overlapping.

70.The middle slot of the scraper conveyor is divided into two types:open bottom and closed bottom.

71.Post safety responsibility system of scraper conveyor?

Answer:(1)Workers without training or qualification certificates are not allowed to work;

⑵Concentrate your thoughts when starting the machine and pay attention to the signal at all times;

(3)Four inspections on each part of the machine.Implement the package mechanism to always keep the device in good condition.

⑷The implementation of"one perseverance","three do","four diligent"and"four strict".

72.What are the signs of chain breakage of the scraper conveyor?

Answer:The symptom of chain scraping of the scraper conveyor is:when the scraper conveyor is running,the scraper chain suddenly sags or accumulates under the head;the scraper chain of the double side chain suddenly skews on one side.

73.How does the scraper conveyor work?

Answer:The scraper conveyor uses an infinitely circulating scraper chain that bypasses the head sprocket and tail roller as the traction mechanism,carries the coal through the chute,drives the motor to drive the hydraulic coupling and reducer to drive the sprocket,the sprocket and The meshing of the scraper chain drives the scraper chain to run continuously,so as to transport the coal to the unloading section of the machine head to achieve the purpose of transportation.

74.What is the function of the chain tightening device of the scraper conveyor?

Answer:The function of the tightening chain device is to adjust the tightness of the scraper chain.

75.What are the specific requirements for the overlap of scraper conveyors?

Answer:When the two conveyors are lapped and transported,the length of the lap is not less than 500mm;the distance between the lowest point of the machine head and the highest point of the tail is not less than 300mm

76.What are the specific requirements for the overlap of scraper conveyor and belt conveyor?

Answer:When the scraper conveyor is lapped and transported with the belt conveyor,the lap length and the height difference between the head and the tail are not greater than 500mm.

77.What are the signs of the“floating chain”of the scraper chain?

Answer:The symptom of the"floating chain"of the scraper chain is:the motor makes a very sharp noise;the scraper scrapes too little coal,and a large amount of coal still does not flow through the unloading head at 2-3 minutes.

78.What are the safety devices of the scraper conveyor?

Answer:The safety devices of the scraper conveyor include:broken chain protection device,overload protection device,failure stop protection device,anchor device to prevent the head and tail from tipping over.

79.What are the advantages of magnetic starters?

Answer:(1)Remote operation is possible;

⑵Control switches can be interlocked with each other,and centralized control can be achieved;

⑶Complete protection device,strong safety and reliability.

80.What are the advantages of hydraulic coupling?

Answer:The fluid coupling has good transmission performance and protection performance.The use of the fluid coupling between the conveyor motor and the reducer can realize the motor light-load start or no-load start,and the load starts gently,absorbing impact and eliminating torsion.Vibration,to achieve load balancing in multi-machine drive,protect the motor and the entire transmission system.

81.Precautions when using hydraulic coupling?

Answer:(1)A special person must be appointed to maintain the fluid coupling and inject the working medium according to the regulations;

⑵The working medium used is not allowed to be changed casually,only water medium and incombustible liquid are allowed to be used,taking care not to bring coal powder into the working chamber;

(3)The speed-adjustable hydraulic coupling is filled with oil medium according to regulations;

⑷It is not allowed to change fusible alloy plugs with different melting points at will,and it is not allowed to use other materials to replace fusible alloy plugs and explosive plugs.If it is necessary to change the melting point temperature of the fusible alloy,protective plugs with different melting points must be replaced.The melting point temperature of the fusible alloy plug is generally 110~140℃;

⑸The running time of the braking system is generally not allowed to exceed 1min;

⑹Do not start the load forward and reverse frequently to prevent the temperature of the working fluid from rising.

82.The post responsibility system for bridge transfer machine drivers?

Answer:(1)Familiar with the technical characteristics and safety regulations,operation regulations and operation regulations of the reprinting machine operated;

⑵Check the roof,coal gang,support and other safety conditions around the work place;

(3)Check the reprinter according to the regulations;

⑷The spirit should be concentrated when driving,pay attention to the start,stop,stop number and the operation of the belt conveyor,and start and stop the transfer machine in time;

⑸Pay attention to the carrying situation of the reprinter,and promptly deal with any leaks;

⑹If there is abnormal sound of the reprinting machine and the accident,it should be stopped in time to deal with it;

⑺Clean coal powder at the tail and drum of the belt conveyor;

⑻Prepare spare parts and other consumables;

⑼Cooperate with maintenance workers to pull the transfer machine;

⑽Fill in the work log.

83.What are the provisions of the"Coal Mine Safety Regulations"regarding the use of transfer machines?

Answer:(1)The mobile machine in the mining face must immediately cut off the power and turn on the clutch when the driver leaves after each shift.

⑵The rubber jacket cables of various mobile mining machines on the mining face must be protected from water,impact,squeezing and blasting.Each shift must be inspected to find damage and deal with it in time.

84.How to prevent accidents caused by crushers?

Answer:(1)It is strictly forbidden for operators and other personnel to get close to the working crusher to prevent the rotating parts from hurting people and splashing coal and gangue from hurting people;

⑵The curtain must be hung up and down to prevent the broken coal and gangue from flying out and hurting people;

(3)When the crusher is stuck by a large piece of gangue or other debris,it is strictly prohibited to pry and move it by hand or other tool areas,and it must be stopped before processing;

⑷When it is found that someone in front of the crusher is pulled down by the transfer machine,the operation of the crusher and the transfer machine should be stopped immediately;

⑸Do not switch on when there is no signal or the signal is unclear;

⑹When repairing the crusher or replacing the cutter teeth,be sure to cut off the power and then lock.When the transfer machine or belt conveyor is overhauled or the crusher is broken down,its operation should be stopped and blocked.

85.What is"slip"?

Answer:When the pump wheel speed is greater than the turbine speed,there is a speed difference between the pump wheel and the turbine,called the"slip".

86.What is the energy conversion process of the hydraulic coupling?

Answer:The energy conversion process of the hydraulic coupling is:the mechanical energy of the motor→the mechanical energy of the pump wheel→the momentum of the working fluid→the mechanical energy of the turbine.

87.How does the hydraulic coupling work?

Answer:The motor drives the pump wheel to rotate→drives the working fluid to make a circular motion to generate centrifugal force→drives the turbine blade to rotate→the driven wheel rotates→output torque

88.What are the common torque-limiting hydraulic couplings?

Answer:There are three types of static pressure drain type,dynamic pressure drain type and valve-controlled extended charge type.

89.What are the main structures of the scraper conveyor?

Answer:Transmission device,scraper chain,chute,protection device,chain tightening device,pushing device,coal baffle plate and shovel coal plate.

90.What is the purpose of the crusher?

Answer:The crusher is mainly used to crush large pieces of coal and gangue to prevent damage to the conveyor belt and ensure the normal operation of the retractable belt conveyor.

91.What types of crushers are there?

Answer:Commonly used crusher types are cone crusher,jaw crusher and wheel crusher.

92.What are the possible causes and solutions for the hanging part of the bridge body of the transfer machine?

Answer:Possible causes:the connection bolts are loose or fall off;the welding seam of the connection baffle is cracked;

Treatment method:tighten or fill the bolts;replace with a new connection plate.

93.What are the possible causes of severe slippage of the hydraulic coupling?

Answer:(1)The fluid capacity of the fluid coupling is insufficient;

⑵The transfer machine is seriously overloaded;

⑶The scraper chain is stuck;

⑷The chain tensioner is in working position.

94.What methods are generally adopted for the patrol inspection of the scraper conveyor?

Answer:The patrol inspection generally adopts methods of seeing,touching,listening,sniffing,testing and measuring.

95.What are the uses of scraper conveyor?

Answer:The scraper conveyor is the main transportation equipment of the comprehensive mechanized coal mining face.In addition to transporting coal,it can also be used as the running track of the coal mining machinery and the fulcrum of the hydraulic support movement.Or a rack without chain traction,and also has the functions of cleaning the floating coal on the working face,placing cables,water pipes,emulsion pipes and so on.

96.What is the possible reason why the motor of the scraper conveyor cannot start or stops slowly after starting?

Answer:The load is too large;the electrical circuit is damaged;the voltage drops;the contactor is faulty;too much coal is pulled back;the hydraulic coupling slips.

97.What is the reason for the oil leakage of the sprocket assembly?

Answer:⑴The seal ring or oil seal is damaged;

⑵The bolt of the pressure cover or pressure plate is loose;

(3)Improper installation of the sealing ring and tight fitting;

⑷The screw plug of the roller is loose.

What are the possible reasons for the 98 sprocket assembly bearing temperature being too high?

Answer:The seal is damaged,the lubricant is not clean;the bearing is damaged;the amount of oil is insufficient.

99.What is the reason for the overheating of the reducer housing of the transfer machine?

Answer:The amount of oil in the box is too much or too little;the lubricating oil is used for too long;the bearing is damaged;the inside of the box is not clean.

100.What are the benefits of using the transfer machine in the fully mechanized mining face?

Answer:The use of a transfer machine in the fully mechanized mining face can reduce the number of expansion and disassembly of the retractable belt conveyor during transportation,and raise the load to facilitate loading onto the belt conveyor,thereby speeding up the movement of the coal mining face Speed,increase production efficiency,and increase coal output.