Maintenance and repair of scraper conveyor and belt conveyor

Published:2019-10-14Author:Click:2435

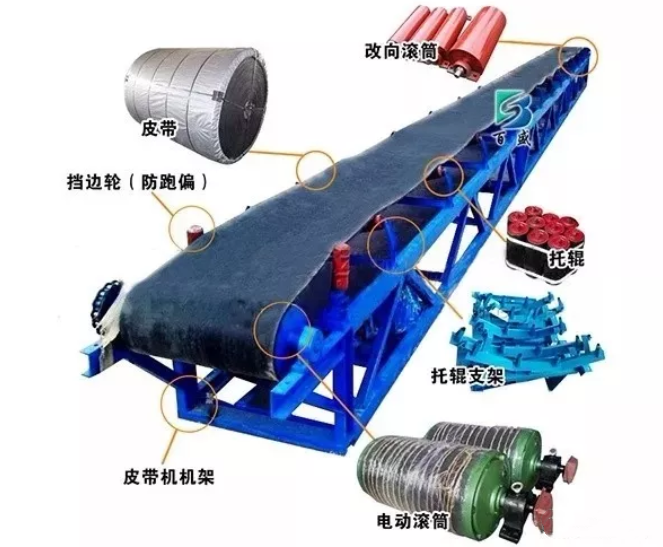

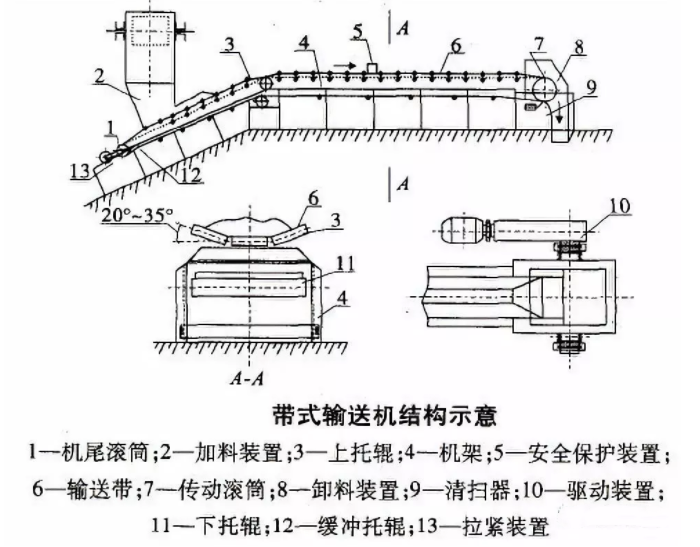

Scraper conveyor belt conveyor and two kinds of ore-mechanical equipment for the production of coal is essential to strengthen these two devices to manage and maintain the use of the process in order to ensure the normal operation of coal production.Due to the particularity of coal mine production,the requirements for safe production are very high.This article shares with you the maintenance and inspection of belt conveyors and scraper conveyors.

1.Preparation before starting

When the belt conveyor is started,make full preparations before starting.Strictly check the safe operating environment of the power transmission system and clean the surrounding environment to ensure that there is no clutter and dirt,whether the pipeline is neat,and mechanical equipment Whether some of the protection devices are in the normal protection state,the tightness of the tape should be strictly notified to prevent various failures during operation.

Strict observation during operation During the operation of the belt conveyor,the corresponding start signal should be issued before starting the machine,and the start can only be carried out after receiving the confirmation response.After the start,the operator should also strictly observe the mechanical equipment issued after starting.The various sound signals ensure the smooth operation of the tape.If the tape position shifts during the operation,it should be dealt with in a timely manner.

3.Preventive measures and precautions

(1)The belt conveyor normally starts when there is no load,and stops after the materials are unloaded.

(2)When personnel work above the belt or repair the belt,the power supply must be turned off and locked.

(3)The operator should stop and lock when leaving the conveyor,and the guardrail at the rear of the belt conveyor must be set on the side.

(4)When the belt conveyor is used to clean coal,debris or other work,it must be in contact with the machine head,and the belt switch should be powered off and locked.After processing is complete,you can input power.

(5)When the belt is running,please do not clean coal,debris or other work.

(6)The feed to the belt conveyor should be evenly fed,and the feed funnel should not be overfilled and the feed funnel will be filled with material and overflow.

(7)The workplace of the belt conveyor should be kept clean.

(8)Ensure that the motor,fluid coupling and reducer have good heat dissipation conditions.

(9)Check the working status of the cleaning equipment.The surface of the conveyor belt and the driving roller after cleaning should not adhere to debris.

(10)When loading,make sure that the materials are placed in the middle of the conveyor belt,and cannot be directly installed at a large height,so as to avoid crushing the conveyor belt of large materials.

(11)In the process of running,care should be taken not to start the device frequently.

(12)Before operation,pay attention to whether the hydraulic linkage shaft leaks oil.Once oil leakage is found,it should be dealt with in a timely manner.Regular oil quantity inspection should be carried out.If the oil quantity is insufficient,it should be replenished in time.

(13)Always check the tension of the steel wire rope of the fuselage.If there is slack,please tighten it immediately.After tightening the rope,pay attention to check that there is no deviation in the conveyor.

(14)The drum should be checked regularly,the grease ring should be filled with grease,and the flexible drum should be replaced immediately.

(15)The conveyor belt does not slip along the driving roller,and the conveyor belt should be tightened immediately if it is loose.

(16)The deviation of the conveyor belt should be corrected immediately,and the edge of the abrasive belt should not appear.

(17)To check the belt joint,it should be repaired or replaced in time.The wedge on the rope clamp should be tight.

(18)There must be no long iron in the conveyed materials to avoid cutting off the conveyor belt when the conveyor belt is disconnected.

4.Laying before use When laying the scraper conveyor before use,you must ensure that the scraper conveyor is laid straight and the joints are stable and tight,and the relevant padding is carried out in the recess.You can use wood to ensure that The head and tail pressure column devices of the conveyor are complete.

5.Lap of the working face and the machine head When the working face and the head of the scraper conveyor are overlapped,a reasonable method should be adopted to maintain a height higher than 400mm to ensure that the bottom chain will not pull back the head material.

6.Inspection of parts and lubrication parts

(1)Make sure that the scraper and screws of the scraper conveyor are complete,and set up the bridge at the position where pedestrians pass through to ensure personal safety.The***tightening chain should be used when the conveyor is unfastened and tightened.To ensure the rigorous work.

(2)During the management process of the scraper conveyor,the conveyor chain should also be inspected and managed to ensure that the chain is properly tightened.Regular lubrication should be performed on the parts that need to be lubricated,and qualified grease should be used to ensure the chain The degree of lubrication.When lubricating and refueling the hydraulic coupler,the power failure should be blocked,and the fusible alloy protective plug should be strictly used,and other items cannot be used instead.

7.Precautions during operation(1)The operator of each scraper conveyor must be operated by***personnel.

(2)During the operation,always pay attention to whether there are heavy objects in the scraper conveyor,and stop to start according to the signal.

(3)When the scraper conveyor fails and cannot be operated,it should be shut down for inspection.It is strictly forbidden to start or reverse the vehicle.It must be closely inspected to find the cause of the failure,and then start the operation after taking corresponding treatment measures.(4)Cautions for scraper conveyors when transporting materials:voice signals can be used to communicate with operators;materials should be smooth and stable;when large materials are transported,personnel must observe the transportation of materials along the way and send messages in time Or signal contact;do not use scraper conveyor for bending materials and overweight and overweight materials.

8.Maintenance of scraper conveyor and transfer machine

(1)During the maintenance process of equipment,standardized operation and maintenance shall be carried out in strict accordance with the relevant provisions of the"Coal Mine Safety Regulations"to ensure accuracy and safety during the entire maintenance process.The maintenance of the conveyor and the maintenance of the support should be carried out at different locations to ensure the safety of the maintenance environment.

(2)Tighten the chain and pinch the chain to run the adjustment chain to the machine head at about 3 meters to stop,fix the chain wedge on the fourth frame,reverse the conveyor belt,one person approaches the brake,wait for it to reach the correct position,tighten Brake and tighten the chain brake to return the conveyor to the forward position,move the conveyor slightly,remove the chain stopper,and then perform a trial run.The order of the tight chain and the chain should be strictly followed,and personnel must avoid the direction of the chain.When tightening the chain,someone must hold the brake and do not loosen or operate the scraper conveyor.

(3)During the maintenance of the scraper conveyor,the operator of the scraper conveyor should ensure the integrity and safety of the bracket on the side of the goaf of the conveyor head,at a position away from the rear of the transfer machine Carry out strict operations and arrange special personnel to take care of the head and tail to ensure the safety of the entire inspection process.

(4)The head of the scraper conveyor and the conveyor should be reasonably overlapped,and the material should not be pulled back.

(5)The gearbox of each equipment,the oiling part of the coupling and the exposed shaft must be protected with iron,the protection device is intact,and the machine tail is transferred.There should be protective iron at the tail of the conveyor on the working face,and bridges should be frequently installed.In the process of mining operations,due to the harsh environment and complexity,especially in the process of mechanized operations,the safety performance requirements are extremely high.Only by strengthening the management of mining machinery and equipment to ensure the safety performance of the use Effectively improve the working efficiency of coal mine production,so as to ensure the economic and social benefits of coal mine production.