100 Cases of Common Knowledge of Scraper Conveyor (Part 1)

Published:2019-06-05Author:Click:1151

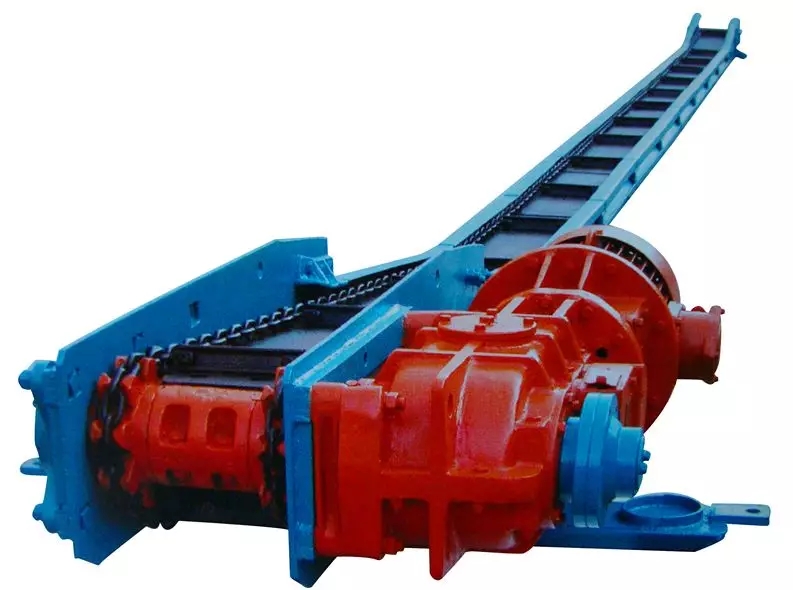

Scraper conveyor is the main coal transportation equipment in the modern coal mining process, mainly divided into general mining scraper and fully mechanized mining scraper.Among them, the comprehensive mining scraper is one of the "three machines and one frame" of modern coal mining, and it is an indispensable coal machine equipment.

Everyone's understanding of scraper machines may sometimes only stay on hearsay. Only frequent contact with scraper machines is really true. This time I share with you 100 common knowledge of scraper (Part 1), it can be said that it is the best in history!

1. It is mainly composed of the nose, middle and tail.

2. Scraper chain is divided into middle single chain, middle double chain, side double chain and quasi-edge double chain according to the arrangement.

3. Scraper conveyor can be used for horizontal transportation or inclined transportation. When transported along inclined transportation, the inclination angle of the coal seam should not exceed 25 °, and when transported downward, the inclination angle should not exceed 20 °.

4. The flexible scraper conveyor is allowed to bend 2 ° ~ 4 ° in the horizontal and vertical directions to facilitate the use of the corresponding shearer and self-moving hydraulic support.

5. The transmission device includes a motor, a coupling, a reducer, and a main shaft.

6. Chute is the guide mechanism of the traction chain and cargo load of the scraper conveyor.

7. Chute can be divided into middle chute, regulating chute and connecting chute.

8. The protection device of the scraper conveyor has a protection pin protection device and a friction plate protection device.

9. The safety device of the scraper conveyor includes a chain break protection device, an overload protection device, a failure stop protection device, an anchor device to prevent the nose and tail from tipping over.

10. Common control switches for scraper conveyors are manual starter and magnetic starter.

11. The role of shoveling coal plate is to put the floating coal on the coal wall into the chute after passing through the chute.

12. The scraper conveyor at the working face must be equipped with a signal device that can send a stop or start along the entire length of the fuselage, and the distance between the signal points should not exceed 15m.

13. When the tandem conveyor is overlapped in a straight line, the background head should be higher than the front end 0.3m before and after 0.5m.

14. When the two scraper conveyors are connected in a straight line, the height of the unloading center should be kept at 0.3m, and when it is greater than 0.5m, a coal skid should be added.

15. When installing and putting into operation, keep the conveyor flat, straight, stable and firm, and pay attention to the tightness of the scraper chain.

16. The scraper conveyor cannot be forcibly started. If the scraper conveyor fails to start or cut off the safety pin three times in a row, the cause must be found and dealt with before restarting.

17. When stopping, the coal flow should be carried out in order from the inside to the outside, and the coal rock on the scraper conveyor should be pulled away.

18. “Four inspections” refers to shift inspection, daily inspection, weekly inspection and monthly inspection.

19. "One perseverance" refers to perseverance in work positions.

20. "Three achievements" refers to the neatness of equipment and environment, the absence of floating coal in the machine head, machine path and tail, and the realization of a civilized production environment.

21. "Four diligence" refers to diligence in maintenance and inspection, diligence in inspection, diligence in handling oil injection problems, diligence in cleaning the head and tail coal storage pit.

22. "Four strict" refers to strict implementation of operating procedures, strict on-site delivery, strict inspection system and strict compliance with labor discipline.

23. Itinerant inspection generally adopts methods such as seeing, touching, listening, sniffing, testing and measuring.

24. The number of inspections per tour should be no less than 2-3.

25. The melting point temperature of fusible alloy protection plug is generally 110 ~ 140 ℃.

26. The running time of the hydraulic coupling under braking conditions is generally not allowed to exceed 1min.

27. Bridge transfer machine is a kind of intermediate transfer transportation equipment commonly used in mining face.

28. When driving the roadway, the transfer machine can be used as a conveyor for the driving face and can be used in conjunction with the retractable belt conveyor to transport coal and gangue during the driving process.

29. The bridge transfer machine is composed of three parts: nose, fuselage and tail.

30. The effective lap length of the transfer machine and the retractable belt conveyor is 12m.

31. The signal must be sent before the transfer machine is started. After no one is working on or near the transfer machine, jog it and start it 2 or 3 times, then start it officially.

32. When the transfer machine is used in the coal roadway, the moving method can be moved by the winch traction, the horizontal oil cylinder of the hydraulic support and the specially-designed moving hydraulic cylinder.

33. The mobile machine in the mining face must cut off the power and open the clutch immediately after each shift and when the driver leaves the machine.

34. The crusher is mainly used to crush large pieces of coal and gangue to prevent damage to the conveyor belt and ensure the normal operation of the retractable belt conveyor.

35. Commonly used crusher types are cone crusher, jaw crusher and wheel crusher.

36. The driver of the crusher must pass the training and examinations and hold a certificate.

37. The crusher should be started under no-load conditions, the time of two jogs should not be less than 90s, and the number of continuous jogs should not exceed 5 times.

38. When handling large pieces of coal, rock and gangue on the transfer machine, the crusher should be blocked.

39. The crusher should check the operation of the sliding clutch 3 times a week to ensure safe operation.

40. When there is no centralized control system, the start of multiple scraper conveyors should start from the outside to the inside in the direction of the reverse coal flow.

41. When the scraper conveyor transports materials, there must be a special person to pick up the material at the transportation site. When two people move materials from the chute at the same time, the rear end should be moved first, and then the front end should be moved to avoid injury.

42. The maintenance content of the scraper conveyor includes the patrol inspection during operation to replace some wearing parts in time, adjust the scraper chain, tighten the bolts and strengthen the lubrication.

43 A special person must be appointed to maintain the fluid coupling and fill the working medium as required.

44. The working medium used in the fluid coupling is not allowed to be changed casually, only water medium or inflammable liquid is allowed.

45. If you need to change the melting point temperature of the fusible alloy, you must replace the protective plugs with different melting points.

46. When the two conveyors are overlapped and transported, the overlap length is not less than 500mm; the distance between the highest point of the nose and the highest point of the tail is not less than 300mm.

47. When the scraper conveyor and the belt conveyor are overlapped and transported, the overlap length and the height difference between the head and the tail are not greater than 500mm.

48. The fluid coupling has good transmission performance and protection function.

49. The use of a hydraulic coupling between the conveyor, the motor and the reducer can realize the motor light-load start or no-load start, the load starts gently, absorbs shock and eliminates torsional vibration, and realizes load balancing in multi-machine drive Protect the motor and the entire transmission system.

50. The fluid coupling observes the law of conservation of energy and the theorem of momentum.